Blog

What Paper Do You Use to Heat Press a Shirt?

In the ever-evolving world of custom apparel, heat pressing has emerged as a popular technique for creating stunning and personalized designs on shirts. The process involves transferring vibrant graphics onto fabric using heat and pressure, resulting in long-lasting and eye-catching prints. A crucial element of this process is the choice of heat press paper, which directly impacts the quality and durability of the final design. This article delves into the world of heat press paper, shedding light on its types, benefits, and factors to consider when selecting the right paper for your heat pressing projects.

Importance of Heat Pressing in the Custom Apparel Industry

Before we dive into the intricacies of heat press paper, let’s understand why heat pressing has become a staple in the custom apparel industry. This technique offers a streamlined way to apply intricate and colorful designs onto fabric, ensuring precise details and vivid results. Unlike traditional methods, heat pressing eliminates the need for excessive manual labor and allows for consistent, professional-looking prints.

Understanding Heat Press Paper

Heat press paper serves as the intermediary between the design and the fabric. It plays a pivotal role in ensuring the successful transfer of ink from the paper to the fabric under the influence of heat and pressure. Selecting the right type of heat press paper is essential for achieving vibrant, durable, and wash-resistant designs.

Types of Heat Press Paper

Inkjet Transfer Paper

Inkjet transfer paper is a popular choice for creating customized designs on various fabrics using an inkjet printer. This type of paper allows you to print your desired design and then transfer it onto the fabric using heat and pressure.

Characteristics:

Versatile: Inkjet transfer paper works well on cotton and cotton-blend fabrics.

Soft Finish: Designs transferred using inkjet paper often have a soft feel, making them comfortable to wear.

Vibrant Colors: Inkjet printers can reproduce vibrant colors, resulting in eye-catching designs.

According to the fabric color, it is divided into light-colored fabric inkjet transfer paper and dark-colored fabric inkjet transfer paper.

Advantages and Limitations of Using Inkjet Transfer Paper

Advantages:

Ease of Use: Inkjet transfer paper is easy to use, making it a good choice for beginners.

Affordable: It’s usually cost-effective, especially for small-scale projects.

Wide Availability: Inkjet printers are commonly available, making it convenient to print designs.

Customization: Ideal for creating personalized designs with intricate details.

Limitations:

Feel: The transferred design might have a slightly noticeable texture on the fabric.

Durability: While designs can last, they may not be as durable as those created with other methods.

Wash Care: Some inkjet transfer papers require specific washing instructions to preserve the design.

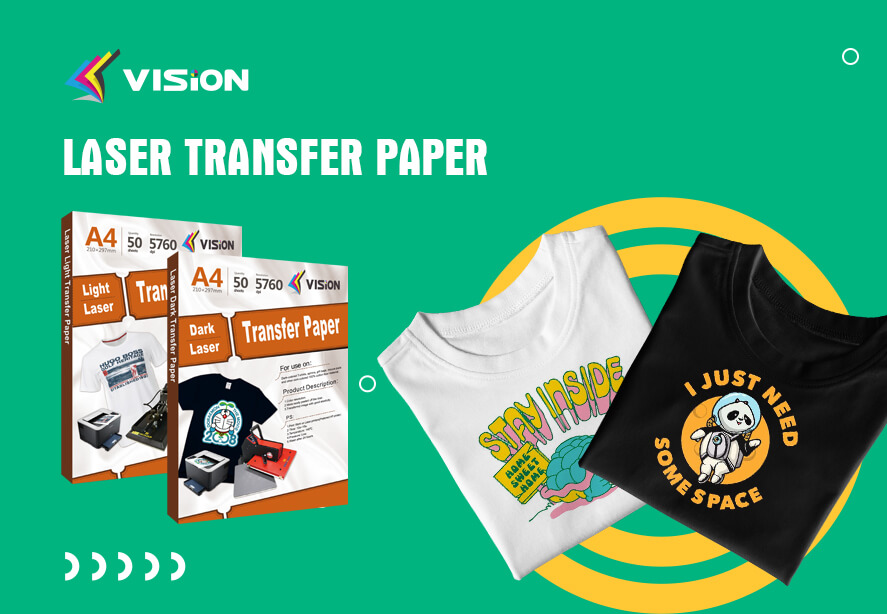

Laser Transfer Paper

Laser transfer paper utilizes toner from a laser printer to create the design, which is then transferred onto the fabric.When the design is transferred to fabric using heat and pressure, the toner adheres to the fabric fibers, creating a permanent design.

Characteristics:

Versatile: Laser transfer paper works on a variety of fabrics, including cotton and polyester blends.

Precise Details: Laser printers can produce intricate and detailed designs, making it suitable for complex graphics.

Durable Results: Designs created using laser transfer paper tend to be durable and wash-resistant.

Smooth Finish: The transferred design typically has a smooth feel on the fabric.

Advantages and Limitations of Using Laser Transfer Paper

Advantages:

Detail Clarity: Laser printers can reproduce fine details and text more accurately.

Longevity: Designs transferred using laser paper often have excellent wash durability.

Quality: Laser transfer paper designs generally have a professional and high-quality appearance.

Fabrics: Laser transfer paper can be used on both light and dark fabrics.

Limitations:

Initial Cost: Laser printers and the associated paper can be more expensive upfront.

Learning Curve: Properly adjusting printer settings for optimal results may require some experimentation.

Fabric Compatibility: Some laser transfer papers are not suitable for certain fabric types.

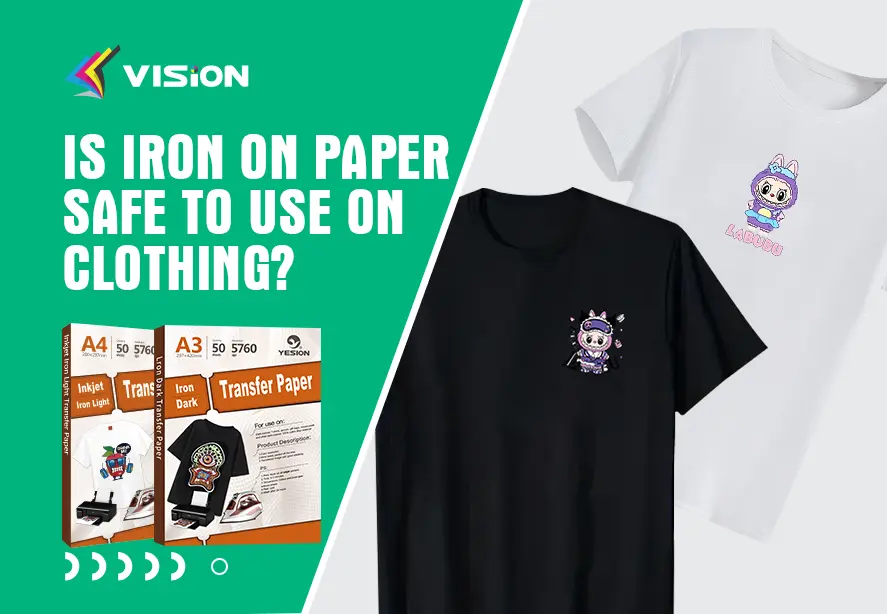

Inkjet Iron-On Transfer Paper

Inkjet iron-on transfer paper is a user-friendly option for creating personalized designs on fabric using an inkjet printer and a household iron.

Details about Inkjet Iron-On Transfer Paper

Inkjet iron-on transfer paper allows you to print your design onto the paper, which has an adhesive backing. When the design is transferred to fabric using heat, the adhesive binds the design to the fabric fibers.

Inkjet iron-on transfer paper is a suitable option for creating customized apparel at home, such as T-shirts, tote bags, and more.

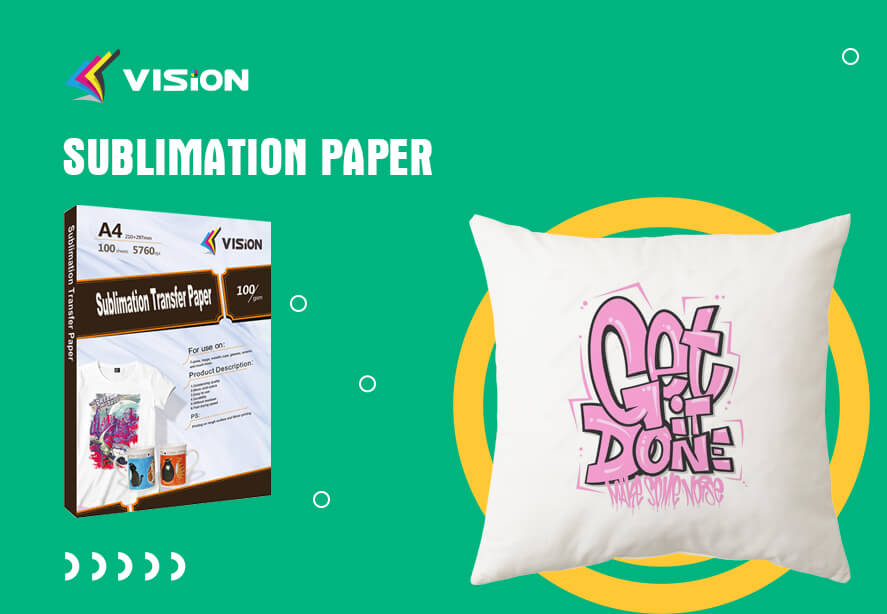

Sublimation Paper

Sublimation paper is a unique type of heat press paper.It works by transforming ink into a gas when exposed to heat. This gas then permeates the fabric’s fibers and solidifies upon cooling, resulting in vivid and long-lasting designs that become part of the fabric itself.

Unique Properties:

Vibrant Colors: Sublimation creates designs with unparalleled color vibrancy and saturation.

Durability: Sublimated designs are resistant to fading, cracking, and peeling.

Polyester Compatibility: Sublimation works best on polyester fabrics due to the molecular structure of polyester.

When and Why to Choose Sublimation Paper

Sublimation paper is an ideal choice when:

Polyester Fabric is Used: Sublimation paper is specifically designed for polyester and polyester-blend fabrics.

Complex Graphics: It’s perfect for intricate designs, photographs, and full-color graphics.

Vividness is Essential: Sublimation produces unmatched color vibrancy and sharpness.

Each of these different types of heat press paper for shirts has its advantages and limitations for a variety of fabrics, design complexities, and preferences. Choosing the right type of paper ensures that your heat-pressed designs turn out vibrant, durable, and precisely as you envision.

Factors to Consider When Choosing Heat Press Paper

Fabric Type

Different fabrics require different types of heat press paper. For example, cotton and polyester blends have distinct requirements. Choosing the right paper for the fabric type ensures optimal results and longevity.

Printer Compatibility

Using heat press paper that’s compatible with your printer type is crucial. Whether you have an inkjet, laser, or sublimation printer, make sure to select paper that works seamlessly with your equipment.

Design Complexity

The complexity of your design influences paper selection. Simple designs may work well with basic transfer paper, while intricate graphics benefit from sublimation or laser heat transfer paper.

Longevity and Wash Resistance

Durability matters, especially if you want your designs to withstand multiple washes. Some papers offer better wash resistance than others, so choose accordingly.

Step-by-Step Guide: Using Heat Press Paper

Preparation

Begin by preparing your design. Remember that some types of transfer paper require mirror printing in order for it to transfer properly to the fabric. Set up your heat press machine and ensure your workspace is clean and organized.

Printing the Design

Print your design onto the chosen heat press paper. Adjust printer settings to optimize color vibrancy and clarity.

Cutting and Weeding

Carefully cut out your design from the paper and weed out any excess material. This step is essential for ensuring a clean transfer.

Heat Press Application

Place the design onto the fabric, aligning it properly. Follow the recommended time, temperature, and pressure settings for the specific type of heat press paper you’re using.

How to use vision inkjet light heat transfer paper for tshirt business? If you are interested in more videos, please follow up our YOUTUBE.

Tips for Getting Professional Results

Achieving professional and polished heat-pressed designs requires attention to detail and a touch of finesse. Whether you’re a novice or a seasoned pro, these tips will help you elevate your heat pressing game and ensure that your creations stand out:

Temperature and Pressure: Understanding the optimal temperature and pressure settings for your chosen heat press paper is essential. Consult the paper’s instructions and perform test runs to find the right balance that yields the best results.

Practice on Scrap Fabric: Before working on your final piece, practice on a scrap piece of fabric. This allows you to fine-tune your technique, familiarize yourself with the process, and make any necessary adjustments.

Design Placement: Precise design placement is crucial. Take your time to align the design accurately on the fabric to ensure a professional finish.

Fabric Preparation: Iron the fabric before applying the design to create a smooth surface. This ensures even heat distribution and prevents wrinkles from affecting the final result.

Avoid Steam: When using an iron, ensure it’s set to the appropriate heat setting without steam. Steam can interfere with the adhesion of the design.

Cooling Time: Allow the fabric to cool slightly before peeling off the transfer paper. This helps the design set properly and minimizes the risk of smudging.

Washing Instructions: Follow the washing instructions provided with the heat press paper. Proper care ensures that the design remains vibrant and intact after multiple washes.

Precision Cutting: When cutting out your design, take your time to create clean and precise edges. This attention to detail contributes to a professional appearance.

Use Quality Equipment: Invest in a reliable heat press machine and printer. High-quality equipment contributes to consistent and professional results.

Ink Quality: If using an inkjet printer, ensure you’re using high-quality ink cartridges. Subpar ink can affect color vibrancy and design longevity.

Avoid Overheating: Be cautious not to overheat the fabric, as it can lead to scorch marks or damage. Follow recommended time and temperature guidelines closely.

Test Different Papers: Experiment with various heat press papers to discover which ones work best for your specific projects and desired outcomes.

Layering Designs: If layering multiple designs, follow a logical sequence to avoid overlapping and ensure a seamless integration of the designs.

Patience: Heat pressing is an art that requires patience. Take your time at each step, from preparation to pressing, to achieve impeccable results.

By embracing these tips, you’re well on your way to producing professional-grade heat-pressed designs that captivate and endure. Whether you’re creating custom apparel, accessories, or personalized gifts, the artistry lies in the meticulous execution that turns ordinary fabric into extraordinary expressions of creativity.

In conclusion, the world of heat press paper is a dynamic realm, offering a diverse array of options to bring your creative visions to life. From the versatility of inkjet transfer paper to the precision of laser transfer paper, and the vibrant magic of sublimation paper, each type presents its own set of strengths that can be harnessed to achieve stunning results. Whether you’re an aspiring designer, a passionate DIY enthusiast, or a professional in the custom apparel industry, the choice of heat press paper can significantly impact the quality and longevity of your creations.

In a world where individuality is celebrated and creativity knows no bounds, VISION Factory stands as your partner in turning visions into reality. Embrace the endless possibilities that heat press paper presents, and let your designs radiate with vibrancy, durability, and character. The fabric becomes the canvas, the paper your medium, and the heat press your conduit to crafting masterpieces that leave an indelible mark on the world.

Related:

Do you need a heat press for transfer paper?

The 4 Types of Inkjet Transfer Paper for Heat Press

Frequently Asked Questions

Transfer paper holds ink for transfer, while sublimation paper turns ink into gas for vibrant results on polyester fabrics.

No, different types of paper are designed for specific fabrics and printers. Using the right paper enhances the outcome.

Yes, most heat press paper is designed for single use to ensure the best quality and results.

Choose a paper known for its wash resistance and follow care instructions. Washing inside out can also help maintain the design’s longevity.

While possible, using a heat press machine yields more consistent and professional results.