Blog

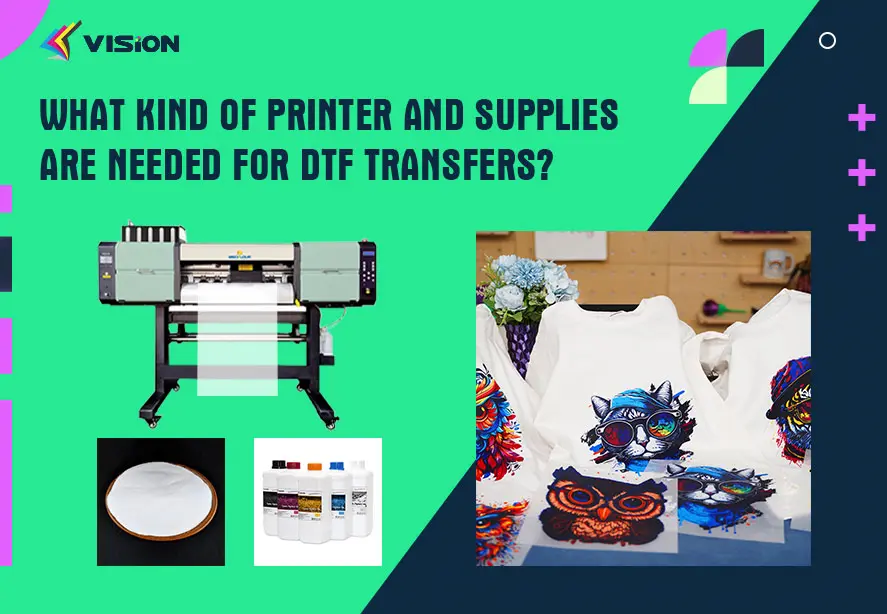

What kind of printer and supplies are needed for DTF transfers?

DTF (Direct-to-Film) printing is rapidly gaining popularity in the custom apparel industry for its ability to print vibrant designs on a wide range of fabrics. To achieve the best results in DTF transfers, it’s essential to have the right printer and supplies. In this guide, we’ll explore the equipment and materials necessary for successful DTF printing, ensuring your business thrives in producing top-quality prints.

Key Equipment for DTF Transfers

1. DTF Printer

The core of DTF printing is the DTF printer. These printers are typically modified inkjet printers capable of printing on specialized transfer films. When selecting a DTF printer, you’ll need to consider the following:

- Ink System: The printer must support DTF inks, including CMYK and white ink. The white ink acts as a base for the colors, ensuring that designs appear vibrant on both light and dark fabrics.

- Resolution: High-resolution printers will deliver crisper and more detailed prints. Look for printers that offer at least 1440 x 1440 dpi resolution for the best results.

- Print Size: Depending on the size of the designs you plan to print, choose a printer with an appropriate print width. Most commercial DTF printers can handle A3 or A4-sized films, but larger formats are available for oversized prints.

Popular choices for DTF printers include Epson models that have been converted for DTF use. These printers are affordable and reliable, making them a top choice for small businesses.

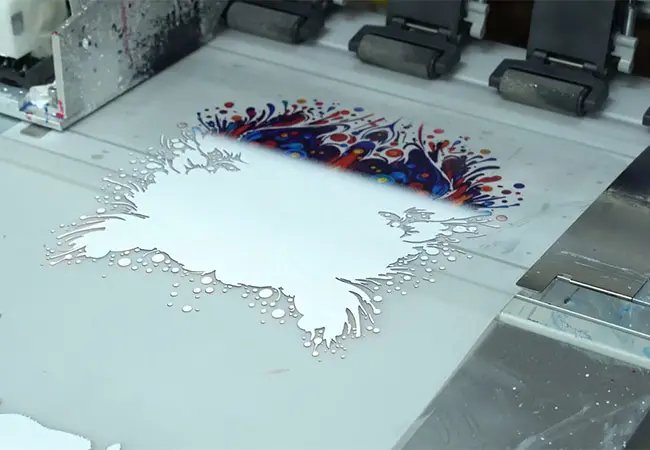

dtf film printing

2. RIP Software

To effectively manage and prepare designs for DTF printing, you’ll need RIP (Raster Image Processor) software. RIP software controls color output, ink levels, and print quality. It also allows for underbase printing, which is essential when using white ink. Popular RIP software for DTF printing includes Acrorip and CADlink Digital Factory.

3. Heat Press Machine

Once the design is printed onto the transfer film, it must be transferred to the garment using a heat press machine. The heat press applies heat and pressure, bonding the design to the fabric. When choosing a heat press, consider the following factors:

- Temperature Control: The machine should have precise temperature settings, as DTF transfers typically require heat between 300-320°F.

- Pressure Adjustability: Proper pressure ensures that the design adheres to the fabric without any distortions. Look for machines that allow for easy pressure adjustments.

- Size: Choose a heat press that matches the size of your DTF prints. A heat press with a 15″ x 15″ platen size works well for most DTF applications.

heat pressing

4. Curing Oven or Heat Gun

After printing, the DTF transfer needs to be cured. You can cure the printed transfer film either using a curing oven or a heat gun. The curing process melts the adhesive powder applied to the transfer, allowing it to bond with the garment.

- Curing Ovens: These ovens provide even and controlled heat, ensuring consistent curing across large batches of transfers.

- Heat Guns: For smaller operations, a heat gun is an affordable option, though it requires manual application and can be less precise.

Essential Supplies for DTF Transfers

1. DTF Transfer Film

DTF transfer film is specially coated to receive the ink and adhesive powder required for successful transfers. The film typically comes in rolls or sheets and varies in size, with A3 and A4 sheets being the most common for smaller prints.

The quality of the transfer film is crucial to the final print quality. High-quality films will result in sharp details and vibrant colors on the transferred design.

2. DTF Inks

The key to producing vibrant and long-lasting prints is using DTF inks. These inks are formulated to adhere to the transfer film and the fabric, ensuring that the design remains durable through multiple washes. DTF inks are available in CMYK (cyan, magenta, yellow, black) and white. The white ink is essential for providing opacity, especially when printing on dark fabrics.

3. Adhesive Powder

DTF adhesive powder is what bonds the ink to the fabric. After printing your design onto the film, you’ll sprinkle the adhesive powder over the wet ink. The powder sticks to the ink and, when heated, melts to form a strong bond between the film and fabric.

There are different grades of adhesive powder, typically categorized by their micron size. Fine powders work well for soft fabrics, while coarser powders may be better for heavy-duty textiles like canvas or denim.

4. Pre-Treatment Solution (Optional)

In some cases, applying a pre-treatment solution to fabrics before transferring the design can enhance the print’s durability and brightness. This is especially true for fabrics that are difficult to print on, such as polyester blends or nylon.

How To Print DTF Transfers At Home

To learn The DTF Printing Process Step-by-Step, please visit The Ultimate Guide to DTF Printing.

DTF printing offers unparalleled versatility, allowing you to print intricate and vibrant designs on almost any fabric. With the right equipment and supplies—such as a DTF printer, RIP software, heat press, and adhesive powders—you can produce professional-quality transfers that stand out from the competition.