What is uv dtf transfers?

In recent years, the printing industry has witnessed remarkable innovations, one of which is UV DTF Transfer. This cutting-edge technology has transformed the way we approach printing on various surfaces, providing unparalleled versatility, precision, and quality. In this comprehensive article, we delve into the details of UV DTF Transfers, exploring what they are, how they work, and why they have become a preferred choice for both businesses and hobbyists alike.

Understanding UV DTF Transfer Technology

UV DTF Transfer, which stands for Ultra-Violet Direct to Film Transfer, is a process that allows for the direct transfer of designs onto a wide array of hard substrates, including plastics, glass, and more. This technology utilizes UV-cured inks, which are printed onto a specialized film. The film is then transferred onto the desired surface, adhering firmly without the need for heat pressing or other traditional methods.

How Does It Work?

The UV DTF Transfer process involves several key steps that ensure the highest quality results:

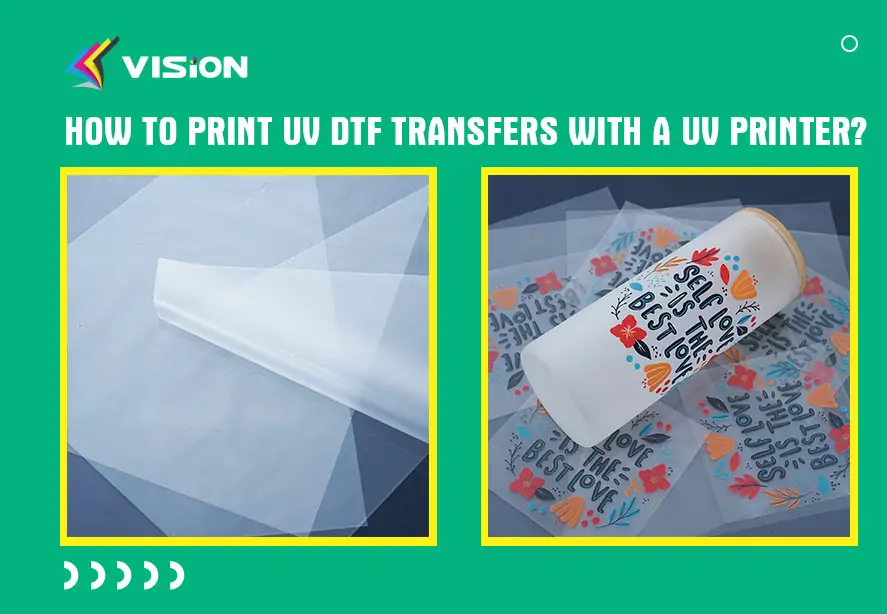

Design Creation: The process begins with the creation of the design using graphic design software. This design is then printed onto a transparent film using a UV DTF printer equipped with special UV inks.

Film Preparation: After the design is printed onto the film, a layer of adhesive is applied. This adhesive layer is what allows the design to bond with the substrate during the transfer process.

Curing Process: The UV inks are cured instantly as they are exposed to ultraviolet light, ensuring that the print is durable and resistant to fading or scratching.

Transfer Application: Once the film is prepared, it is carefully aligned with the substrate and pressed onto the surface. The design adheres to the material, and the film is then peeled away, leaving a crisp, vibrant print.

uv dtf work

Advantages of UV DTF Transfers

UV DTF Transfers offer numerous advantages over traditional printing methods, making them an ideal choice for a wide range of applications:

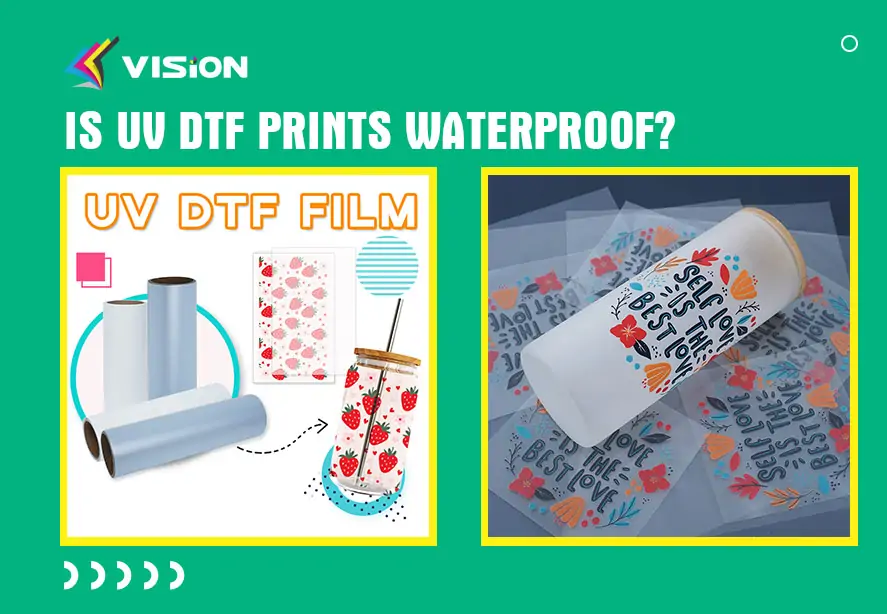

Versatility: One of the most significant benefits of UV DTF is its ability to adhere to various hard surfaces. Whether printing on ceramics, wood, or metal, UV DTF provides consistent, high-quality results.

Durability: The UV-cured inks used in this process are known for their exceptional durability. Prints created with UV DTF are resistant to wear and tear, UV exposure, and even chemical damage, making them ideal for products that will be exposed to harsh environments.

Vibrant Colors: UV DTF Transfers are renowned for their ability to produce vibrant, true-to-life colors. The curing process locks in the colors, ensuring they remain vivid and sharp over time.

Eco-Friendly: Unlike traditional screen printing, UV DTF does not require solvents or excessive water usage, making it a more environmentally friendly option.

Applications of UV DTF Transfers

UV DTF Transfers have a broad range of applications, spanning various industries and creative endeavors:

Promotional Products

UV DTF is a popular choice for creating promotional products such as mugs, pens, and keychains. The ability to print on curved and irregular surfaces makes UV DTF an excellent choice for branding and marketing purposes.

Signage and Displays

For businesses, UV DTF provides a reliable method for producing signage and displays. The prints are weather-resistant, ensuring that outdoor signs remain vibrant and intact, regardless of exposure to the elements.

Decorative Arts

Artists and designers utilize UV DTF Transfers to add intricate designs to home décor items such as vases, plates, and picture frames. The precision of the UV DTF process allows for the reproduction of fine details and complex patterns.

uv dtf transfers

Why Choose UV DTF Over Other Printing Methods?

When compared to other printing techniques, UV DTF Transfers stand out for several reasons:

No Need for Heat Pressing: Unlike traditional heat transfer methods, UV DTF does not require a heat press to transfer the design. This reduces the risk of damaging the substrate and allows for a quicker, more efficient production process.

High Resolution: UV DTF offers unparalleled resolution, making it possible to print even the smallest details with incredible accuracy. This is particularly important for designs that require intricate patterns or fine text.

Cost-Effective: For small to medium production runs, UV DTF is a cost-effective option. The process eliminates the need for screens or plates, reducing setup costs and allowing for greater flexibility in design changes.

Customizability: UV DTF is highly customizable, allowing for quick adjustments to designs without the need for new equipment or materials. This flexibility is ideal for businesses that offer personalized products.

UV DTF Transfers represent a significant advancement in the world of printing, offering a versatile, durable, and cost-effective solution for creating high-quality prints on a variety of substrates. Whether you’re in the business of fashion, promotional products, signage, or decorative arts, UV DTF provides the tools needed to produce stunning, long-lasting designs that stand out from the competition. As the technology continues to evolve, we can expect UV DTF to play an increasingly important role in the future of printing.

Related:

How to print UV DTF transfers with a UV printer?

How long does UV DTF Prints last?