What is the various terms used for heat transfer vinyl?

As a professional company who has been engaged in the heat transfer industry for many years.I will tell you three important variables when applying heat transfer vinyl with a heat press machine: pressure, temperature, and time. Being accurate on these three variables is essential to creating a good print. Disregarding the guidelines will result in anything from a design that doesn’t stick to a blemished, ruined garment.

Once you’ve chosen your heat transfer vinyl and cut/weeded it, it’s time to apply. If you’ve done the groundwork and know the vinyl will work well with your fabric, you’re more than halfway there. Follow these steps to decorate your item:

This article will teach you about various terms used for heat transfer vinyl; the different types of Heat Transfer Vinyl ; how to cut, weed, and apply Heat Transfer Vinyl ; and the different types of equipment you will use.

Carrier

The clear, shiny backing on the Heat Transfer Vinyl . The carrier can be tacky or smooth, depending on the Heat Transfer Vinyl type. Carriers can come in low, medium, and high-tack backings. High-tack carriers are the best choice for more intricate designs.

Cavities

Cavities are the center portions of the design where excess vinyl surrounds the design. The center of an “0”is an example of a cavity.

Peel

heat-transfer-vinyl-peel

After heat application, you need to peel the carrier away from the vinyl. Which peeling method you choose depend on the Heat Transfer Vinyl you use, the options are hot, warm, and cold peel.

Hot Peel-Peel carrier right away while the design is still hot from the press. No waiting necessary!

Warm Peel-Wait until the carrier cools down slightly and peel carrier away when it is warm to the touch.

Cold Peel – Let the carrier cool down completely before peeling away the carrier.

It has several advantages as follow:That is the reason we choose Heat Transfer Vinyl.

Soft Hand

heat-transfer-vinyl-soft-hand

When Heat Transfer Vinyl has a “soft hand”, it is both soft to the touch and lightweight. Materials with a soft hand feel like it is a part of the shirt.

Stretch & Rebound

heat-transfer-vinyl-rebound

Stretch and rebound have to do with the flexibility of the Heat Transfer Vinyl . When materials stretch, they rebound back to their original shape once stretched. This factor is important when talking about active wear or jerseys that need to have Heat Transfer Vinyl that move with the garment. Volleyball jerseys are a perfect example of ordering Heat Transfer Vinyl.

Vinyl Cutter

Vinyl cutters are the equipment choice for do-it-yourself production of heat transfers. Use them with heat transfer vinyl, screen printed transfers, or transfer paper to create one-of-a-kind designs for apparel or for personalized print-on-demand orders. The cutter cuts the design into the vinyl, allowing for weeding of the excess vinyl.

Weed

Weeding is the act of cutting the excess vinyl from a design, leaving only the need design on the heat transfer vinyl.

Vision Heat Transfer Vinyl is a vinyl used to decorate apparel, bags, and other soft goods. Unlike adhesive vinyl or sign vinyl,Heat Transfer Vinyl is printed onto an item using heat and pressure.

How many colors does vision have?

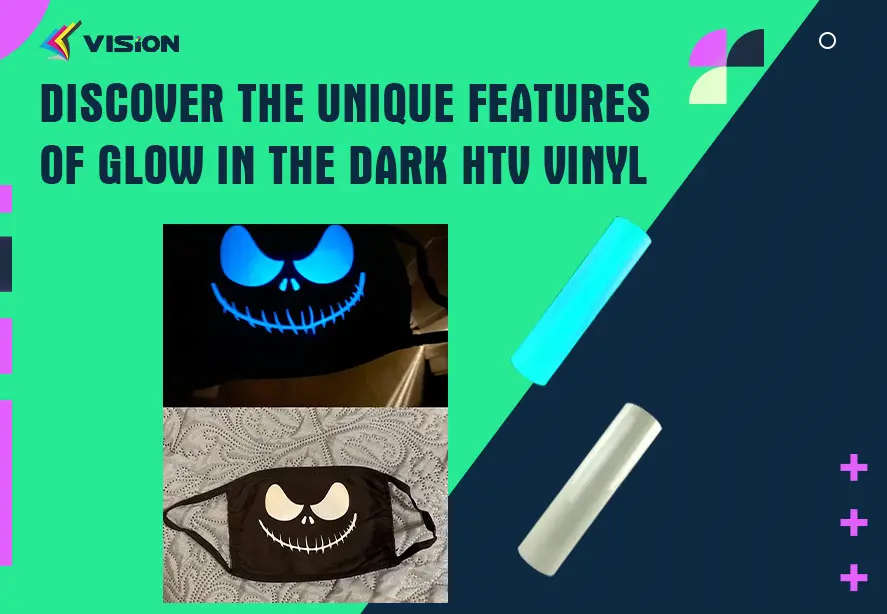

Vision heat transfer vinyl has some series,including PU heat transfer vinyl,fluorescent heat transfer vinyl,pattern heat transfer vinyl,glitter heat transfer vinyl,metallic heat transfer vinyl,soft metallic heat transfer vinyl,you can get the details of the products in our website.Of course,these don’t just include solid colors.Furthermore,there are various colors in each series.You can create all type of designs that can work for business apparel, sport uniforms or fashionable bling.

So what material do you apply with heat transfer vinyl?It depends on the fabric/textiles.Just as there are many different types of garments, there are different types of Heat Transfer Vinyl to decorate them.

If you have any questions about vision heat transfer vinyl,please let us know!

Contact us:

Whatsapp: +86-18001836806

E-mail: info@visionsub.com

Web: https://www.visionsub.com/