Precautions|Some common problems on transfer paper for t-shirts

Heat transfer T-shirt is a kind of T-shirt made by printing heat transfer paper on blank T-shirt.Heat transfer paper for t-shirts is a very important consumable in thermal transfer. It is a special heat transfer paper on which various patterns are printed using special thermal transfer inks. and then the patterns are transferred onto the garments through temperature and pressure. This special paper in the thermal transfer process is called heat transfer paper.

Many customers may encounter problems when they use the heat transfer paper.As a leading manufacture for global clients,Vision will tell you some common problems and attentions about transfer paper for t-shirts.

1.The color is light

If you are an expert,you should know the color will be lost during the heat transfer process.First of all, you should increase the brightness and contrast,but darken the color of the picture in the drawing software.Only in this way can you ensure that the transfer is the effect you want.

In addition, do not print the picture that has just been printed out immediately. It should be left for a period of 3-8 minutes (according to the climate at the time) and allow the ink to penetrate into the paper about 5 minutes or more.

The light color may be used for a longer time. You can try to reduce the time and increase the temperature. In addition, the heat transfer paper can only be used once, and do not reuse it.

2.The pattern is not transferred

It may be that your pressure is not enough, the temperature is low, or the time is too short,so that the pattern is not transferred. First, you should turn up the pressure and increase the time and temperature appropriately.At the same time, you could check whether your printing surface is reversed.

3.The discoloration problem

It is possible that the ink is not the original ink, so the paper has not absorbed it completely. Vision recommends that you use special inks. In addition, the printed clothes should not be washed immediately, but washed after 24 hours. Turn the clothes over and wash them. At the same time, increasing the value of pressure, time and temperature that will prevent the color from fading.

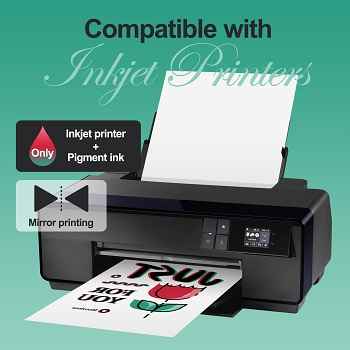

inkjet printer only for pigment ink

4.Washing and fading

Washing and fading has a lot to do with transfer paper and ink. Pigment ink is made of powdered ink, and good quality pigment ink does not dissolve in water. The principle of transfer paper is to use its film to melt the ink at high temperatures, then melted on the cloth. Achieve the “transfer” result. Therefore, the adhesive layer of poor transfer paper will gradually fall off after washing, which will cause color fading. This method has special requirements for the fabric, which must be Khmer material or pure cotton material.

5.The bottom paper cannot be peeled

The light-colored heat transfer paper needs to hot peel after the heat transfer is finished. Once the temperature cools down, it cannot be peeled.

6.The picture is blurred and faint after printing

This is caused by the excessive inkjet volume of the printer. The inkjet volume of the printer can be adjusted through the printer paper selection and the adjustment of the print quality.

7.Precautions for washing

We recommend using ordinary detergent and cold water to wash the transferred T-shirt separately. Do not wash with other clothes at the same time. Do not dry clean or bleach. Please do not rub the transferred part. Dry it immediately after washing or dry it with a dryer. After washing, if the image shows signs of peeling off, you can cover the backing paper on the image and re-iron and bond it. Do not directly iron the transfer part with an iron.

Vision is a trusted heat transfer paper factory,which professionally manufacture digital printing products for many years, such as sublimation transfer paper ,heat transfer paper ,heat transfer vinyl ,DTF transfer,OBM subli-textile.If you need, we can customize heat transfer printing products for you.

If you have any problems about transfer paper for t-shirts,please feel free to contact us.

Whatsapp: +86-18001836806

E-mail: info@visionsub.com

Web: https://www.visionsub.com/