Sublimation Paper Roll: Enhancing Your Printing Experience

In the world of personalized products and promotional materials, sublimation printing has become a game-changer. Whether you’re a business owner, a hobbyist, or a creative individual, sublimation paper rolls play a crucial role in achieving vibrant and long-lasting prints. This article will provide a comprehensive guide to sublimation paper rolls, including their benefits, usage, and valuable tips for optimizing your printing process. So, let’s delve into the world of sublimation paper rolls!

Understanding Sublimation Paper Rolls

Sublimation paper rolls are specialized papers designed specifically for sublimation printing. They act as carriers for transferring ink onto various substrates, such as fabrics, ceramics, metals, and more. These papers are coated with a unique layer that enables the ink to sublimate, converting from a solid to a gas state under heat and pressure. This process allows the ink to permanently bond with the target surface, resulting in exceptional print quality and durability.

Benefits of Sublimation Paper Rolls

2.1 Superior Print Quality

Sublimation paper rolls are renowned for their ability to produce high-quality prints. The unique coating on these papers ensures that the ink is absorbed efficiently, resulting in vibrant colors, sharp details, and excellent color accuracy. The prints produced using sublimation paper rolls are known for their professional finish and exceptional durability, making them ideal for a wide range of applications.

2.2 Versatility

One of the significant advantages of sublimation paper rolls is their versatility. They can be used with various substrates, including fabrics, ceramics, metals, and more. Whether you’re printing custom apparel, mugs, or promotional items, sublimation paper provide a reliable and versatile solution. This flexibility allows you to explore countless creative possibilities and cater to a diverse range of customer needs.

2.3 Fast Drying Time

Sublimation paper rolls offer fast drying times, which is particularly advantageous for businesses and individuals working on tight deadlines. The quick-drying property ensures that you can efficiently move through the printing process, reducing waiting times and increasing overall productivity. This benefit makes sublimation paper rolls an excellent choice for high-volume printing projects.

2.4 Long-Lasting Prints

Durability is a key factor when it comes to printed products. Sublimation paper rolls excel in this area, as the ink becomes permanently embedded within the target surface during the sublimation process. This results in prints that are resistant to fading, scratching, and washing. Whether your prints are exposed to sunlight, frequent handling, or harsh environments, sublimation paper rolls ensure that they stand the test of time.

How to use sublimation paper rolls?

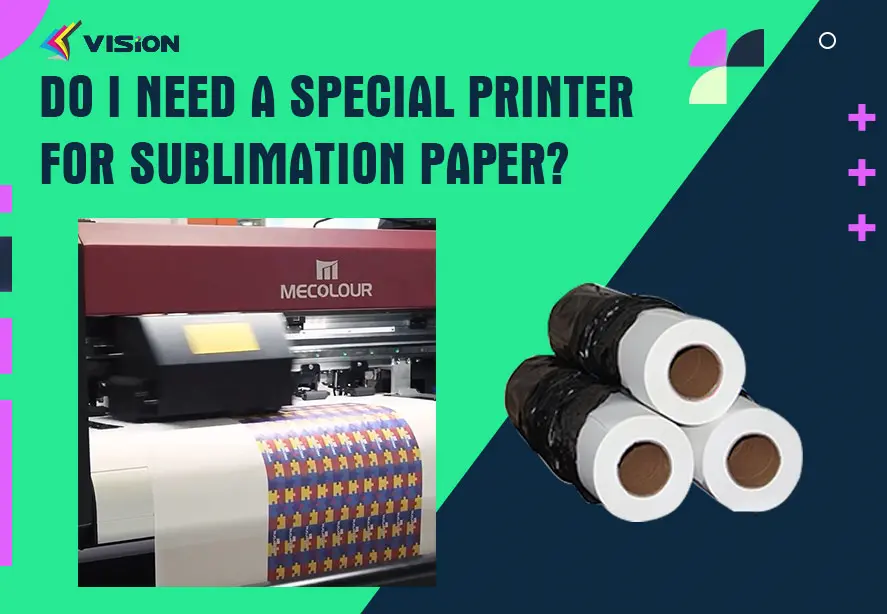

3.1 Printer Settings

Ensure that your printer is set to the appropriate settings for sublimation printing. Adjust the print resolution, paper type, and color management settings according to the recommendations provided by the sublimation paper and ink manufacturers. This will help achieve accurate and vibrant prints.

3.2 Pre-Printing Preparation

Before printing, ensure that the substrate is properly prepared. For fabrics, make sure they are pre-treated with a sublimation coating or are made of polyester or a polyester blend. Clean and pre-press hard substrates to remove any moisture or contaminants that may affect the ink transfer.

3.3 Printing Process

Load the sublimation paper roll correctly into your printer, ensuring that it is aligned properly. Avoid wrinkling or folding the paper during loading. Start the printing process, and monitor the print job to ensure smooth and consistent ink transfer. Avoid handling the printed paper immediately to prevent smudging.

VISION sublimation paper roll is compatible with PRINTER–dgen, Mimaki, Epson, Roland, Mutoh, MS, Regianni.

how to print sublimation paper with 1.8m three 5113 print heads sublimation printer, please watch this video if interested:

3.4 Heat Press Transfer

After printing, carefully transfer the design from the sublimation paper to the substrate using a heat press machine. Follow the recommended time, temperature, and pressure settings for the specific substrate and ink being used. Ensure even and sufficient pressure across the entire design to achieve uniform transfer.

3.5 Post-Processing

Allow the transferred design to cool down before handling. For fabrics, consider using a heat press or a roll-to-roll calendar for post-processing to enhance color vibrancy and durability. Follow the post-processing guidelines provided by the sublimation paper and ink manufacturers for best results.

Valuable Tips for Sublimation Paper Rolls

4.1 Determine the Right Paper Weight

Sublimation paper rolls come in various weights, such as 45gsm, 60gsm, 70gsm, 80gsm, 90gsm, 100gsm and 120gsm. These sizes are what we can provide, and can also be customized according to customer needs. Consider the nature of your project and the desired outcome when selecting the appropriate paper weight. Thicker papers are generally more suitable for high-quality prints and heavier substrates, while lighter papers work well for fabrics and lighter materials.

4.2 Conduct Test Prints

Before starting a large printing project, it’s advisable to conduct test prints. This allows you to assess the color accuracy, sharpness, and overall print quality. Adjust the printer settings and make necessary tweaks to achieve the desired results before proceeding with the actual production.

4.3 Use the Right Side of the Paper

Sublimation paper rolls usually have a printable side and a non-printable side. It’s important to load the paper into the printer with the printable side facing up. The printable side is typically smoother and coated with a specialized layer to facilitate ink absorption and transfer.

4.4 Maintain Proper Heat Press Temperature

The temperature of the heat press machine is crucial for successful sublimation printing. Follow the recommended temperature guidelines provided by the sublimation paper manufacturer. Adjusting the temperature too high may result in color bleeding or scorching, while setting it too low may lead to incomplete ink transfer.

4.5 Ensure Even Pressure

When using a heat press machine, ensure that there is even pressure applied across the entire surface of the sublimation paper. Uneven pressure can result in uneven ink transfer, leading to inconsistent print quality. Adjust the pressure settings of your heat press machine accordingly and ensure that the substrate and paper are aligned properly.

4.6 Time and Peel Technique

The time spent during the heat press process can significantly impact the final result. Follow the recommended pressing time provided by the sublimation paper manufacturer. Additionally, pay attention to the peel technique after heat pressing. Some papers require a hot or cold peel, where the transfer paper is peeled off immediately or after it cools down. Adhering to the correct peel technique ensures optimal color vibrancy and print durability.

Sublimation paper rolls are essential tools for achieving exceptional prints in the world of sublimation printing. Their superior print quality, versatility, fast drying time, and long-lasting results make them indispensable for businesses, hobbyists, and creative individuals. By following the tips mentioned above, you can optimize your sublimation printing process and create stunning, customized products. So, harness the power of sublimation paper rolls and unlock endless possibilities in your printing endeavors.