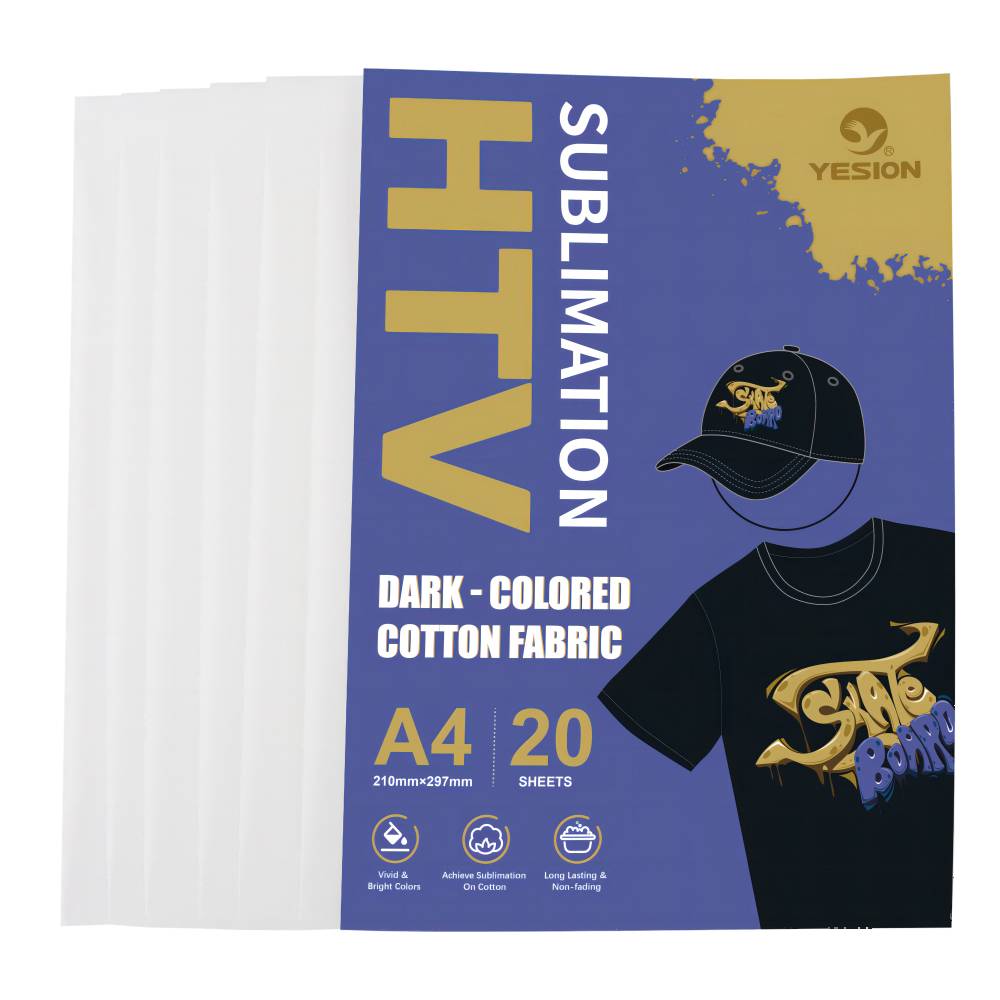

Sublimation Vinyl Sheet For Dark-colored Cotton Fabrics

Specification

| Surface material |

PU face film |

|---|---|

| Film thickness(with glue) |

0.14mm |

| Glue type |

Silica glue |

| Release paper |

PET |

| Color |

White |

| Available sizes |

A4/A3/12inX12in/12inx82ft |

What’s sublimation on black shirt?

The sublimation vinyl on black fabrics perfectly solves the problem that sublimation paper cannot transfer dark-colored pure cotton shirts.

Sublimation HTV for Dark Fabric is made with new technology and is suitable for dark cotton fabrics, providing personalized and unique designs for your T-shirts, backpacks, hats, pillows and more.

Sublimation vinyl covers the heat pressed film with a protective film, which has strong adhesion, easy to weed and cut, the protective film is easy to separate after heat pressing, no wrinkles or bubbles.

Easily apply intricate and multi-colored graphics to T-shirts and other wearable apparel with sublimation heat transfer vinyl! Patterns with a hollow effect can be achieved, and the transferred colors are vivid and bright, with good firmness and washability.

How to do sublimation on dark fabric?

Materials needed

Computer, printer, Sublimation ink, Cutting plotter, Tool set, Heat press machine, dark fabric.

Opertation

Step 1:

Obtain a pattern, import the pattern into the operating software of the cutting plotter, and print the designed pattern with sublimation ink through the software of the cutting plotter.

Print Mode: Mirror Print, High Quality Glossy Paper, Standard Print Quality.

Note: Record the size settings of the printed pattern.

Step 2:

Re-upload the pattern to the software of the cutting plotter (Note: The size of the pattern needs to be the same as the printed pattern), then click the offset and set the distance of the outline to 0.1mm and cut out the pattern (if the pattern is complex and small, the offset can be appropriately increased; if it is simple and the offset can be appropriately reduced).

Take out the sublimation vinyl, cut out the outline edge of the pattern by the cutting plotter, and then weed the extra parts. (Note: Cutting Mode:Mirror).

Step 3:

Transfer the pattern.

Set heat press parameters: Temperature: 185℃, Pressure: medium.

Put the sublimation HTV vinyl face up on the fabric, iron at 185℃ for 5 seconds, and remove the base film of the sublimation vinyl (Cold Peel).

Put the printed sublimation paper on the sublimation vinyl,Align and fix the pattern.Iron with a heat press machine at 185°C for 45 seconds, peel off the sublimation paper(cold peel).

Step 4:

Transfer completed.

Note: If the pattern is not easy to align during transfer, you can also put a positioning film on the back of the sublimation paper, and then use a cutting plotter to cut the pattern on the sublimation paper and then weed the extra parts,in order to align the pattern during transfer.

Factory Profile

Heat Transfer Vinyl Manufacturers & Suppliers From China

VISION is a Chinese manufacturer specializing in the production of thermal transfer consumables. Our heat transfer vinyl factory covers an area of 15,000 square meters, and we can produce 50,000 to 60,000 square meters of heat transfer vinyl per day.

China heat transfer vinyl manufacturer

In order to improve the quality of products as the goal, strive to produce high quality performance products. We have been committed to the production, research and development and sales of environmentally friendly heat transfer vinyl.

The Heat Transfer Vinyl Production Process

HTV production process

We always consider the safety of users and the pursuit of beautiful things by consumers, and only produce products that are environmentally friendly and of stable quality. Therefore, our thermal transfer film has been well received and recognized by the customer base. The current heat transfer vinyl series include PVC HTV vinyl,PU HTV vinyl,soft metallic HTV vinyl, glitter HTV vinyl, flock transfer vinyl and printable HTV vinyl,glow in dark heat transfer vinyl and more products.

Now, we have produced and supplied more than 200 colors of HTV vinyls, and continue to develop new products for our customers, all the heat transfer vinyls can effectively solve the bonding problem of all kinds of materials.

Our heat transfer vinyl is widely used in clothing decoration, shoes, hats, bag accessories decoration, car interior, building materials, electronic industry and other applications.

Heat Transfer Vinyl Sample Room

HTV sample room

The goal we pursue is “always meet the needs of the market”. Strive to produce and develop the best quality thermal transfer material solutions for our old and new customers. Our solutions have won praise from customers around the world. Our heat transfer vinyls have been supplied to all over the world, such as Europe, America, Australia, Africa, Latin America. We will continue to work hard to expand the scale of international trade and exports, so that more countries in the world can use our products.

Become our company’s distributor and agent to make your business more profitable, welcome new and old customers to inquire and get free samples for you to test! We can also provide you with OEM and ODM services.

FEATURES

![]() Sublimation on dark-colored cotton fabrics.

Sublimation on dark-colored cotton fabrics.

![]() Vivid & Bright Colors.

Vivid & Bright Colors.

![]() Easy to Use & Transfer.

Easy to Use & Transfer.

![]() Long Lasting & Non-fading.

Long Lasting & Non-fading.

![]() Soft hand & very flexible.

Soft hand & very flexible.

![]() Washable & Light fastness.

Washable & Light fastness.

APPLICATIONS

Sublimation vinyl is widely used on most material: 100% Cotton, 100% Polyester, Poly / Cotton Blends,such as dark colored clothes, Canvas bags, Hats, Socks, Pillows, Baby clothing and more.

DOWNLOADS

Instructions

![]() PDF-Download:English

PDF-Download:English