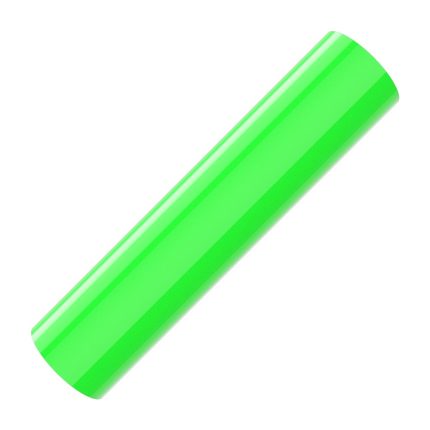

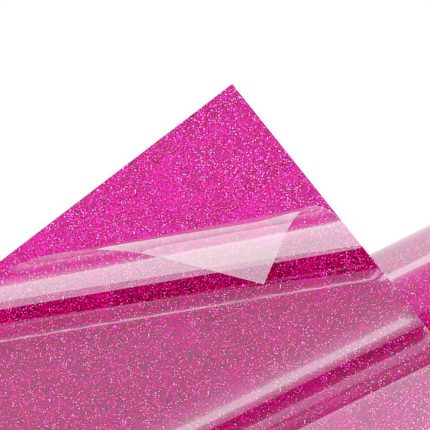

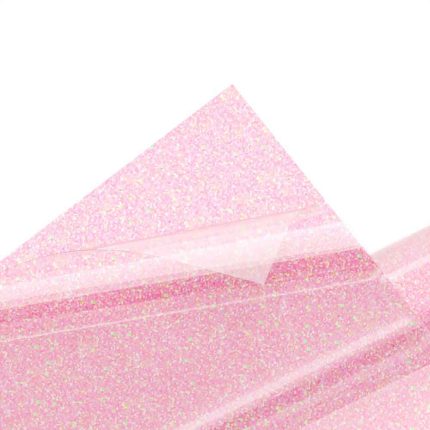

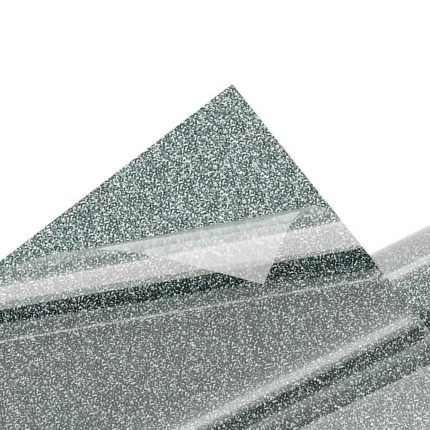

Silicone PU heat transfer vinyl (PUH-Y03)

$1.00

| Size |

45cmx20m |

|---|---|

| Thickness |

0.5mm ,1mm |

| Transfer Pressure |

Medium |

| Transfer Temperature |

160 Celsius |

| Transfer Time |

20s |

| Peel |

Hot |

| Package |

1Roll/Carton |

| Suitable |

Cutting plotters and laser machines |

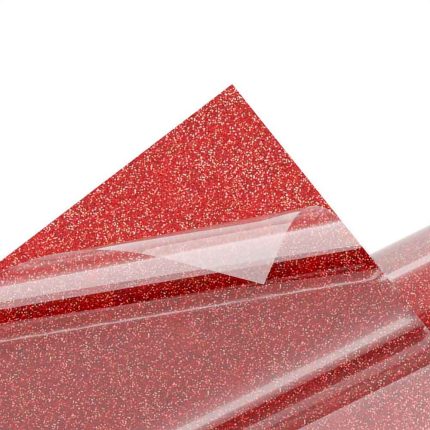

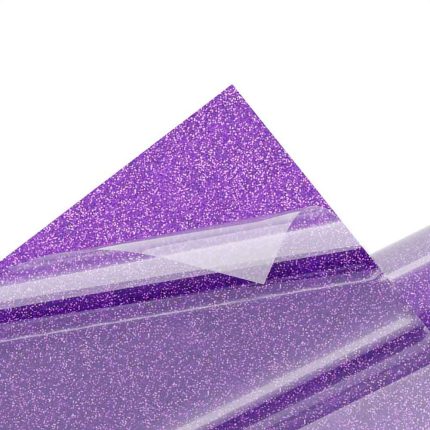

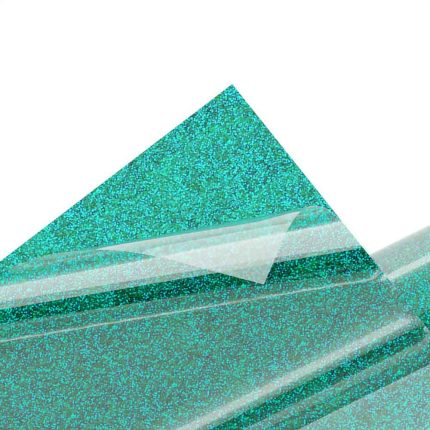

Red Silicone PU heat transfer vinyl is used to transfer designs, logos, and other graphics onto fabrics using heat and pressure. It is made from a silicone polyurethane material that is highly durable, flexible, and resistant to abrasion, chemicals, and high temperatures.

The vinyl is designed to be used with a vinyl cutter or plotter to create custom designs, which can then be transferred onto a range of materials including cotton, polyester, nylon, and more.

The vinyl is then placed onto the garment or fabric and pressed using a heat press or iron. The heat and pressure activate the adhesive, causing the vinyl to bond with the fabric.

How to use Silicone PU heat transfer vinyl

Design: Create or obtain the desired design for your project. The design must be in vector format, as this will allow for accurate cutting of the vinyl.

Cut: Use a vinyl cutter to cut the design out of the Silicone PU heat transfer vinyl. Be sure to adjust the settings on your cutter to match the thickness of the vinyl you are using.

Weed: Remove any unwanted vinyl from the design using a weeding tool. This process is called “weeding” and is essential for achieving a clean final product.

Prepare textile item: Prepare the textile item by washing and drying it to remove any dirt or debris that may interfere with the vinyl’s adhesion.

Heat press: Use a heat press to transfer the vinyl design onto the textile item. Set the temperature and pressure settings on your heat press to the recommended levels for your vinyl type and the textile item you are using. Place the vinyl design onto the textile item, cover it with a sheet of parchment paper, and press for the recommended time.

Peel: Once the pressing is complete, peel the transfer paper from the vinyl design while it is still warm.

Finished product: Your custom design should now be successfully transferred onto the textile item.

Factory Profile

Heat Transfer Vinyl Manufacturers & Suppliers From China

VISION is a Chinese manufacturer specializing in the production of thermal transfer consumables. Our heat transfer vinyl factory covers an area of 15,000 square meters, and we can produce 50,000 to 60,000 square meters of heat transfer vinyl per day.

China heat transfer vinyl manufacturer

In order to improve the quality of products as the goal, strive to produce high quality performance products. We have been committed to the production, research and development and sales of environmentally friendly heat transfer vinyl.

The Heat Transfer Vinyl Production Process

HTV production process

We always consider the safety of users and the pursuit of beautiful things by consumers, and only produce products that are environmentally friendly and of stable quality. Therefore, our thermal transfer film has been well received and recognized by the customer base. The current heat transfer vinyl series include PVC HTV vinyl,PU HTV vinyl,soft metallic HTV vinyl, glitter HTV vinyl, flock transfer vinyl and printable HTV vinyl,glow in dark heat transfer vinyl and more products.

Now, we have produced and supplied more than 200 colors of HTV vinyls, and continue to develop new products for our customers, all the heat transfer vinyls can effectively solve the bonding problem of all kinds of materials.

Our heat transfer vinyl is widely used in clothing decoration, shoes, hats, bag accessories decoration, car interior, building materials, electronic industry and other applications.

Heat Transfer Vinyl Sample Room

HTV sample room

The goal we pursue is “always meet the needs of the market”. Strive to produce and develop the best quality thermal transfer material solutions for our old and new customers. Our solutions have won praise from customers around the world. Our heat transfer vinyls have been supplied to all over the world, such as Europe, America, Australia, Africa, Latin America. We will continue to work hard to expand the scale of international trade and exports, so that more countries in the world can use our products.

Become our company’s distributor and agent to make your business more profitable, welcome new and old customers to inquire and get free samples for you to test! We can also provide you with OEM and ODM services.

FEATURES

Touch Soft;

Achieve three-dimensional effect;

Achieve double color effect;

Cooperate with embossing machine to achieve embossing effect;

Both cutting plotter and laser machine can be used (100um is more suitable for large logo);

Realize the production of small batch three-dimensional logo.

APPLICATIONS

The Silicone PU heat transfer vinyl is designed to be used with a vinyl cutter or plotter to create custom designs, which can then be transferred onto a range of materials including cotton, polyester, nylon, and more.