How to use DTF Printing Film?

1. Required equipment and consumables

6-color inkjet printers (A4/L805 and A3/L1800 desktop printers, it should be noted that the machine must be artificially modified and used with RIP software).

5 colors of paint ink, C, M, Y, K, W (the ratio of color ink and white ink consumption is 45:100);

DTF film (thickness 7.5 microns, size A4, A3, roll 0.60*100m and 0.30*100m).

Shaking heat press machine or oven (the distance between the direct pressure heating plate and the bottom plate is too high, the heating is uneven, and it is not easy to be heated; We recommend to use an oven).

Hot melt adhesive powder (particle size 80-170 microns).

Flat Tray (it is recommended to use plastic trays, iron and stainless steel trays may generate static electricity, resulting in uncertain situations later).

2. Operation process

Print the pattern on the digital printing film with textile printing ink.

Sprinkle the hot melt adhesive powder on the printed pattern immediately after the printing is completed (to prevent the pattern ink from drying and the hot melt adhesive powder cannot stick to the pattern), shake off the excess hot melt adhesive powder on the pattern.

Set the temperature of the heat press machine to 180°C, place the printed film in the middle of the backing plate, bake for 40-50S, and then melt the glue powder and spread on the pattern.

The temperature of the heat press machine is set to 180℃, the time is 8-10S, the heat press machine is pressed down, and the pattern is transferred to the fabric.

3. Attentions

The printing software used by the DTF printer is required for printing. After importing the image into the software, it should be noted that the pattern should not be too close to the top and left and right edges of the DTF transfer film, and the trailing edge should be left blank about 3-4CM; It should be noted that after a piece of film is printed, the film needs to be removed from the paper tray. After printing, the ink is wet. If it is not removed, the pattern on the second film will be scratched off.

The format of the printed picture must be in PNG format with transparent bottom. Pay attention when designing the picture; the transferred picture can be hollowed out. It is recommended that the hollowed-out pattern should not be dense small lines. Part of the rubber powder is difficult to shake completely clean, destroying the effect of transfer.

When dusting, let the printing film pass through the middle of the hot-melt adhesive powder, so that the adhesive powder is evenly sprinkled on the pattern. After dusting, the adhesive film needs to be shaken. Do not directly touch the adhesive powder with your hands. you can shake off the glue powder on the edge of the pattern.

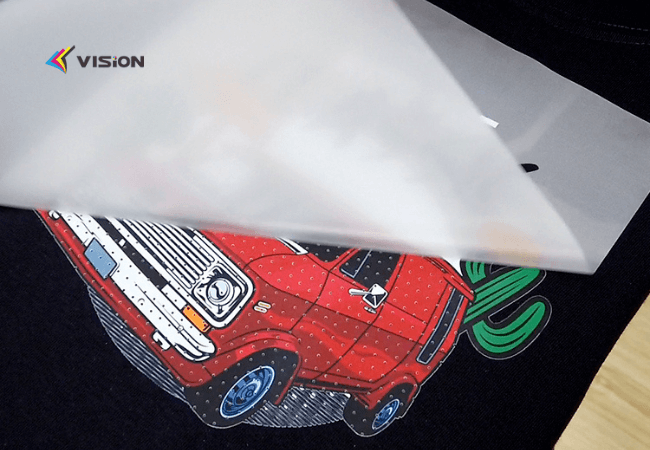

When putting the film into the DTF printer, it is recommended to wear plastic gloves to prevent the sweat on your hands from sticking to the coating, resulting in the white ink not covering the pattern evenly, as shown in the figure below; in addition, the coating of the transfer film is very thin. Because the film is thin, it is necessary to pay attention to prevent damage to the coating when taking the film, resulting in the coating not absorbing ink.

It is recommended to wear gloves when shaking DTF powder to prevent sweat from sticking to the film. If there is sweat on the film, it will cause the DTF powder to stick to the film, and it will melt on the film during baking. When printing, it will be transferred to the fabric at the same time, destroying the effect of the transfer.

There are two ways to bake hot melt adhesive powder:

First, bake the heat press machine, set the temperature of the heat press machine (here you need to use a shaking head heat press machine) to 180°C, place the pattern in the middle of the bottom half of the heat press machine, just below the heating plate, bake for 40 -50S, that is, the hot melt adhesive powder can be melted; Second, bake in the oven, set the oven temperature to 100°C, heat up and down, preheat the oven for 2-3 minutes, then place a piece of paper or a thin template on the tray of the oven, and place the printed pattern on the film. On the paper, put it in the oven to bake for 40-60s, pay attention to observe that the glue powder is melted and can be baked. When the A3 size or large-format pattern is baked, it is recommended to use the oven to bake. When baking with a heat press machine, there will be a part of the glue powder. It has been completely melted, and a part of the glue powder has not yet begun to melt. Such a state will affect the firmness after transfer. The baking time should not be too short. If the time is too short, the glue powder will not be completely melted. It will be granular; the baking time should not be too long, the time will be too long, resulting in excessive melting of the glue powder and cracking of the pattern.

When transferring, set the heat transfer machine to 180°C, 8-10S, and medium pressure.

The DTF film needs to be peeled warmly and coldly after transfer. It is recommended to tear it cold, not hot tearing. Hot tearing will cause the rubber powder not to be completely melted on the fabric, which will affect the firmness.

Precautions for washing:

- Wash after 24 hours of transfer printing.

- Turn the clothes over and wash them.

- Do not bleach, dry, or soak for a long time.

- It can be hand washed or machine washed.

VISION is a China DTF printing factory, we provide all dtf printing related consumables for global customers,any need or question,please let us know!