How Long Do Custom Sublimation Transfers Last?

The durability of sublimation transfers is closely tied to the quality of materials. High-quality polyester fabrics are essential because sublimation dye bonds best with polyester fibers. When the garment is a polyester blend (e.g., 50% polyester, 50% cotton), expect lower durability, as dye doesn’t adhere well to cotton.

Additionally, the quality of sublimation ink and sublimation paper plays a role. Using reputable brands can improve both the vibrancy and longevity of transfers.

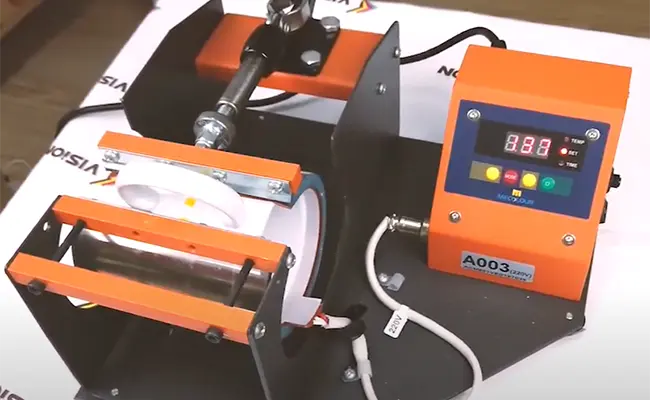

2. Print Conditions

To achieve the best sublimation results, temperature and pressure during the transfer process must be optimal. Most transfers are applied with a heat press set between 385°F to 400°F, with a pressing time of 45–60 seconds. The right temperature, time, and pressure ensure that the dye bonds securely to the fibers, enhancing durability.

mug press

3. Washing and Care Instructions

One of the primary ways to extend the life of sublimation print transfers is by following appropriate care instructions. Key washing and drying practices to maintain the lifespan include:

Wash in cold or warm water: Hot water can deteriorate fibers more quickly.

Turn garments inside out: This reduces friction and exposure to detergents, helping retain color.

Avoid bleach and harsh detergents: Use gentle, dye-safe detergents.

Air dry or use a low heat setting in dryers: High temperatures in dryers can weaken fibers and fade sublimation prints over time.

Following these instructions can extend the lifespan of sublimation transfers significantly.

4. Frequency of Use

Items with sublimation transfers that are worn or washed frequently will naturally experience some degradation over time. Although sublimation transfers last longer than traditional prints, daily use and frequent washing may reduce vibrancy faster than occasional wear.

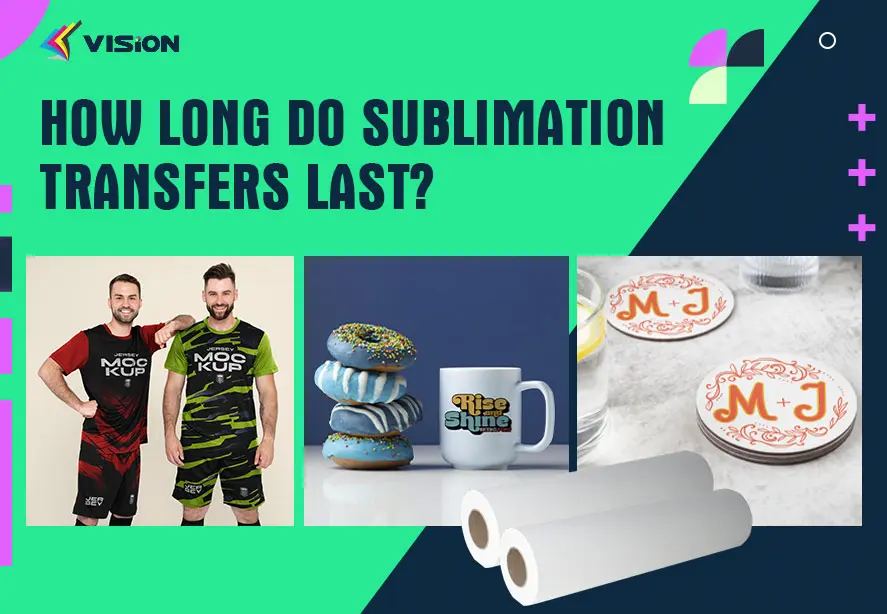

Expected Lifespan of Custom Sublimation Transfers on Various Products

The longevity of sublimation transfers also varies depending on the type of item:

1. Apparel (T-Shirts, Hoodies, etc.)

For garments, high-quality sublimation prints on 100% polyester materials typically last over 50 washes without fading. If the care instructions are strictly followed, the prints can remain vibrant for the garment’s entire lifespan. On a 50/50 polyester-cotton blend, expect colors to fade faster due to the lack of bonding between dye and cotton fibers.

2. Hard Surfaces (Mugs, Keychains, etc.)

Sublimation on hard surfaces such as mugs, keychains, and coasters can last much longer than fabric items. These products don’t undergo frequent washing or wear, and as long as they are not exposed to direct sunlight or extreme heat, the prints can last indefinitely.

3. Home Decor (Pillows, Blankets, etc.)

Items like sublimated pillows and blankets also benefit from less frequent washing, extending the lifespan of the print. These items, when properly cared for, can retain vibrant colors and crisp details for years without significant fading.

Related:

Sublimation Paper Printing on T Shirt

Sublimation paper for tumblers: Tips and Tricks for Success

Why Choose Vision Sublimation Transfer Paper ?

Comparing Custom Sublimation Transfers with Other Printing Methods

When it comes to durability, sublimation transfers stand out in comparison to heat transfer vinyl (HTV), direct-to-garment (DTG), and screen printing. Here’s how sublimation stacks up:

Sublimation vs. Heat Transfer Vinyl (HTV): Unlike HTV, sublimation dye doesn’t peel or crack. HTV adheres to the surface and tends to show wear after numerous washes, whereas sublimation dye is embedded within the fabric, making it far more durable.

Sublimation vs. Direct-to-Garment (DTG): DTG can produce vibrant colors, but the ink sits on the surface, leading to quicker fading and potential cracking. DTG prints typically last 20-30 washes, whereas sublimation can last over 50 washes or more.

Sublimation vs. Screen Printing: While screen printing is highly durable, it doesn’t match the longevity of sublimation for polyester materials. Sublimation is also preferable for intricate designs due to its high-resolution output.

Tips to Maximize the Lifespan of Custom Sublimation Transfers

To further enhance the durability of sublimation prints, follow these practical tips:

1. Choose Polyester or Poly-Coated Products

Always select items with a high polyester content or a polyester coating for hard surfaces. The higher the polyester percentage, the longer your sublimation prints will last. 100% polyester fabrics yield the best results.

2. Avoid Direct Sunlight Exposure

Prolonged exposure to sunlight can cause sublimation dyes to fade. Keep sublimated items out of direct sunlight or use UV-protective sprays on items exposed to the sun.

3. Use Gentle Detergents and Avoid Fabric Softeners

Harsh detergents and fabric softeners can degrade polyester fibers over time, reducing the vibrancy of sublimation dyes. Opt for mild detergents designed for delicate fabrics to prolong the lifespan of sublimation prints.

4. Store Items Properly

For infrequently used sublimated items, proper storage can help maintain print quality. Store items in a cool, dry place, away from direct sunlight or heat sources, to preserve color.

Sublimation transfers offer unparalleled durability for polyester fabrics and poly-coated surfaces. With proper care, sublimation prints can retain their vibrancy for the lifespan of the product, making this printing method ideal for both apparel and hard goods. By understanding the factors that impact the longevity of sublimation transfers, you can make the most of your designs, ensuring they stay vibrant and crisp for years to come. With a few mindful practices in washing and storage, your sublimation transfers can continue to look as vibrant as the day they were made.