How do I test your sublimation transfer paper?

Testing sublimation transfer paper is an important step in ensuring its quality and effectiveness for your specific needs. By conducting various tests, you can evaluate the paper’s color vibrancy, durability, and overall performance.

VISION, as a sublimation paper manufacturer in the digital printing industry, would like to introduce to you how to test our dye-sublimation paper. As an industry leader in China, we want to ensure customers have the best experience possible. We will guide you through the process of testing sublimation transfer paper, providing you with valuable insights to make informed decisions.

To test sublimation transfer paper, you can follow these steps:

Color Accuracy Test

The color accuracy test helps you determine if the sublimation transfer paper accurately reproduces the colors of your design. Follow these steps:

1.Prepare a design with a range of colors, including vibrant and subtle shades.

2.Print the design onto the sublimation transfer paper using a compatible printer and sublimation ink.

3.Apply the transfer paper onto a blank substrate, such as a polyester fabric or coated mug. You can use heat-resistant tape to hold the sublimation paper in place.

4.Use a heat press machine to transfer the design onto the substrate according to the recommended time and temperature settings.

5.Compare the printed colors on the substrate with the original design. Pay attention to any discrepancies or color shifts.

vibrant color

If the colors on the substrate closely match the original design, it indicates that the sublimation transfer paper has good color accuracy.

Durability Test

The durability test assesses how well the sublimation transfer paper holds up over time, ensuring that the colors remain vibrant and the design maintains its quality. Here’s how to conduct the test:

1.Prepare a design with solid colors or intricate patterns.

2.Print the design onto the sublimation transfer paper and apply it to the substrate using the same method as above.

3.Wash the substrate according to the recommended care instructions, such as machine washing or hand washing.

4.Examine the substrate for any signs of fading, color bleeding, or deterioration after washing.

5.Repeat the washing process multiple times to assess the paper’s long-term durability.

If the design remains intact without significant fading or deterioration after repeated washings, it indicates that the sublimation transfer paper is durable.

Transfer Quality Test

The transfer quality test evaluates how well the sublimation transfer paper transfers the ink onto the substrate, ensuring sharp and detailed prints. Follow these steps:

1.Print a design with intricate details and fine lines onto the sublimation transfer paper.

2.Apply the transfer paper onto the substrate using the recommended heat press settings.

3.Peel off the transfer paper carefully to avoid smudging or smearing.

4.Inspect the transferred design on the substrate for sharpness, clarity, and accurate reproduction of details.

If the transferred design exhibits clean lines, sharp edges, and accurate details, it indicates that the sublimation transfer paper provides high-quality transfers.

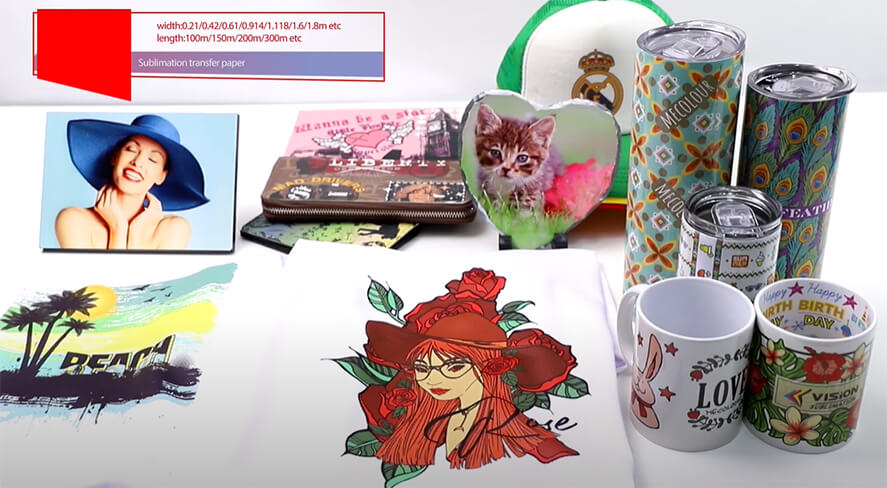

Test for VISION 90gsm sublimation paper

Compatibility Test

The compatibility test determines if the sublimation transfer paper is compatible with your specific printing setup, including the printer, sublimation ink, and heat press machine. Here’s what you need to do:

1.Consult the manufacturer’s guidelines to ensure that the sublimation transfer paper is compatible with your printer and sublimation ink.

2.Follow the recommended printing and heat press settings for the specific transfer paper.

3.Print a sample design onto the transfer paper and apply it to the substrate.

4.Evaluate the print quality, color vibrancy, and overall performance of the transfer paper in conjunction with your printing setup.

If the sublimation transfer paper works seamlessly with your printing setup and produces satisfactory results, it indicates compatibility.

Testing sublimation transfer paper is crucial to determine its color accuracy, durability, transfer quality, and compatibility with your printing setup. By conducting these tests, you can make informed decisions and select the best sublimation transfer paper for your specific needs. Remember to follow the manufacturer’s guidelines and recommendations throughout the testing process to ensure accurate and reliable results.

So when you receive our sublimation paper samples, please test your product as soon as possible. If you encounter any problems during the testing process, please don’t hesitate to contact us to solve any of your problems.

Related:

Our 4 Best Sublimation Paper Types

What sublimation paper is and its role in the sublimation printing process

3 Common problems and solutions of sublimation transfer paper