How do DTF transfer printer handle color accuracy and vibrancy?

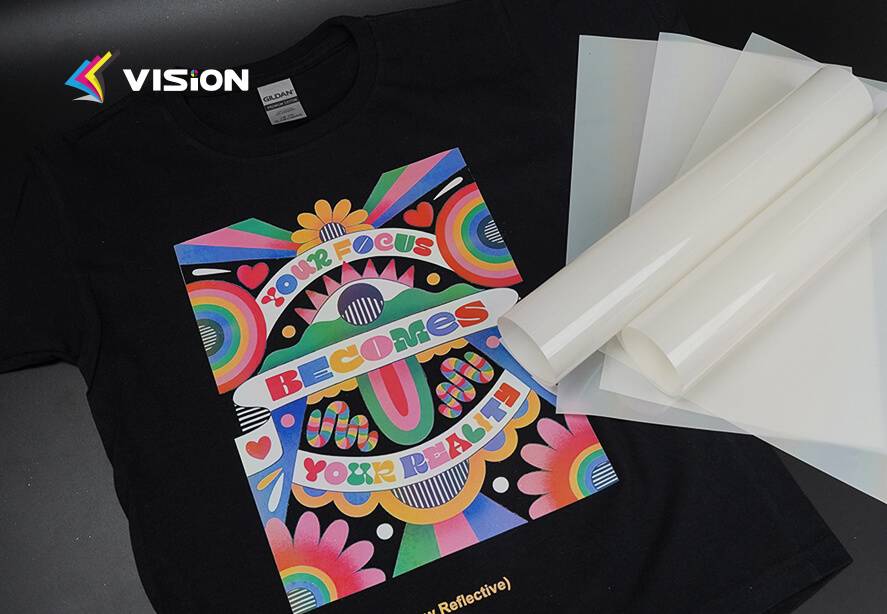

DTF (Direct-to-Film) transfer printers are primarily used for printing designs onto various fabrics, including garments, textiles, and other materials. While DTF printing technology is known for its versatility and ability to reproduce vibrant colors, the color accuracy and vibrancy can be influenced by several factors.

Here are some key considerations:

Ink Quality and Color Gamut: DTF printers utilize specialized DTF inks designed for fabric printing. The quality and color gamut of these inks play a crucial role in achieving accurate and vibrant colors. High-quality inks with a wide color gamut can produce a broader range of colors, ensuring better color accuracy and vibrancy.

Color Management: Proper color management is essential to maintain color accuracy. DTF printers typically employ color management techniques such as color profiling and calibration. Color profiling involves creating ICC profiles for the printer, inks, and specific fabrics to ensure accurate color reproduction. Regular calibration helps maintain consistent and accurate colors over time.

Printing Software: The printing software used with DTF printers often includes color management tools and settings. These tools allow users to control and adjust various color parameters, such as saturation, brightness, and contrast, to achieve the desired color accuracy and vibrancy.

Fabric Selection: The type and quality of the fabric being printed on can impact color accuracy and vibrancy. Some fabrics may absorb or reflect ink differently, affecting the final color result. It’s important to choose fabrics that are compatible with the printer and inks and have good color retention properties.

Printing Technology: DTF transfer printers utilize advanced printing technology, such as piezoelectric printheads, to deliver precise and controlled ink deposition. These printheads are capable of producing tiny ink droplets with high precision, resulting in sharp and vibrant prints. The printing technology ensures that the ink is applied evenly and accurately to the transfer film, allowing for excellent color accuracy and vibrancy in the final print.

How to use glitter gold DTF film step by step?

Pre-treatment and Post-Treatment Processes: DTF printing may require pre-treatment of the fabric before printing to enhance ink adhesion and color vibrancy. Additionally, post-treatment processes like heat curing or pressing can further enhance color vibrancy and durability.

Printer Settings and Maintenance: Proper printer settings, such as ink saturation and printing resolution, can affect color accuracy and vibrancy. Regular maintenance of the printer, including printhead cleaning and ink system maintenance, ensures optimal performance and consistent color output.

Color Calibration and Testing: Regularly calibrating the printer and performing color tests with color swatches or test patterns can help identify and correct any color inaccuracies or inconsistencies. This process allows adjustments to be made to the printer settings or color profiles as needed. By periodically calibrating the printer, any inconsistencies or color shifts can be corrected, resulting in accurate and vibrant prints.

Media Quality: The quality of the transfer film used in DTF printing also influences color accuracy and vibrancy. High-quality transfer films are designed to receive and retain ink in a way that maximizes color saturation and vibrancy. The smooth and uniform surface of the transfer film allows for precise ink transfer, resulting in accurate and vibrant colors.

By considering these factors and implementing appropriate techniques, DTF transfer printers can achieve high color accuracy and vibrant prints, resulting in visually appealing and professional-looking designs on fabrics. VISION is a DTF printing expert from China, If you have any question about DTF printing technology, product use or price, Feel free to contact us any time!

Related:

Share 9 Tips of DTF Printing by factory test

The Ultimate Guide to DTF Printing