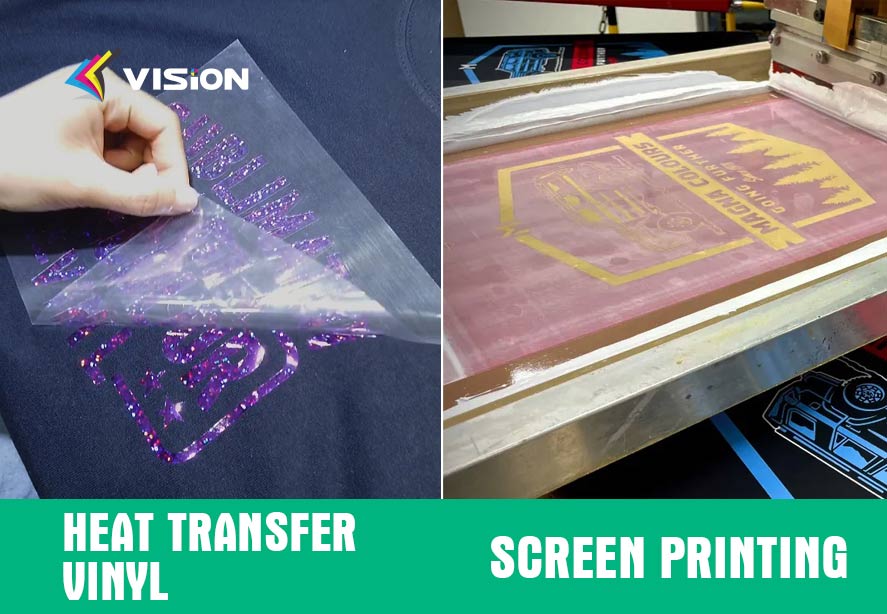

Heat Transfer Vinyl vs. Screen Printing: Comparison

Customized clothing and accessories have become a popular trend, whether for personal use, businesses, or events. As demand grows, the need for efficient and effective printing methods arises. Among the top contenders for custom apparel printing are heat transfer vinyl and Screen Printing. Both methods have their unique qualities that cater to different needs, and understanding their differences is vital for anyone looking to create custom designs.

What is Heat Transfer Vinyl?

Heat Transfer Vinyl, commonly known as HTV, is a process that involves cutting designs from colored vinyl sheets and then applying them to fabric using heat and pressure. This method is widely used for creating custom t-shirts, bags, and other fabric-based products. Heat transfer vinyl allows for precise designs and can handle intricate details with ease.

Advantages of Heat Transfer Vinyl

Durable and Long-Lasting

Heat Transfer Vinyl designs are highly durable and can withstand frequent washing and everyday wear. When applied correctly, the vinyl adheres firmly to the fabric, ensuring that the design remains intact for an extended period.

Suitable for Small Orders

Heat Transfer Vinyl is an excellent choice for small custom orders. It is cost-effective and doesn’t require minimum order quantities, making it suitable for individual projects or small businesses.

Ideal for Multicolored Designs

Heat Transfer Vinyl can accommodate multiple colors within a design without significantly increasing the cost. This makes it an attractive option for vibrant and complex designs.

How many Types of Heat Transfer Vinyl?

VISIONSUB factory offers a wide range of heat transfer vinyl options for customizing clothing and accessories. Each type of HTV brings its unique characteristics and effects to your designs. Here are some popular types of HTV:

VISION heat transfer vinyl factory

1. Holographic HTV

Holographic HTV creates a design with holographic or prism-like effect, which reflects light in a rainbow of colors.

2. 3D Puff HTV

3D Puff HTV adds a raised, textured look to your designs, giving them a three-dimensional effect. It’s perfect for creating a tactile and eye-catching element on garments.

3. Flock HTV

Flock HTV has a velvety or suede-like texture that adds a soft and fuzzy feel to your designs. It creates a unique and luxurious look on apparel and accessories.

4. Glow In The Dark HTV

Glow In The Dark HTV is perfect for designs that need an extra touch of magic. It absorbs light during the day and glows brightly in the dark, making your creations truly standout at night.

5.PVC HTV

PVC HTV offers a glossy and smooth finish that adds a professional look to your custom apparel. It’s known for its durability and resistance to fading, making it suitable for long-lasting designs.

6.Glitter HTV

Glitter HTV adds a sparkling and glamorous touch to your creations. It’s perfect for designs that require some extra dazzle and shine.

7.Metallic HTV

Metallic HTV provides a shiny and metallic finish, perfect for achieving a premium and elegant look on your custom apparel.

8.Chameleon HTV

Chameleon HTV creates a color-shifting effect, where the color changes depending on the angle of view. It adds an element of surprise and uniqueness to your designs.

Of course,Our HTV projects are not limited to these above, to know more, please visit our heat transfer vinyl products.

Each type of HTV brings its distinct characteristics, making it essential to choose the right one for your specific design and project requirements. Explore these options to elevate your custom apparel to a whole new level of style and creativity.

Disadvantages of Heat Transfer Vinyl

Limited Color Range

While heat transfer vinyl offers a variety of colors, the selection might not be as extensive as other printing methods like screen printing.

Not Suitable for Large Orders

Heat Transfer Vinyl can be time-consuming when applied to a large number of garments. It is more suitable for small to medium-sized orders.

Not Recommended for Complex Designs

Intricate and highly detailed designs may not be well-suited for Heat Transfer Vinyl, as the cutting process might lead to loss of small elements or fine lines.

What is Screen Printing?

Screen Printing, also known as silkscreen printing, is a traditional method that involves pushing ink through a fine mesh screen onto the fabric. It is widely used for producing custom apparel, promotional items, and even fine art prints.

Advantages of Screen Printing

Cost-Effective

Screen printing becomes more cost-effective with larger order quantities. As the number of items increases, the price per unit decreases, making it a budget-friendly option for bulk orders.

Great for Large Orders

When it comes to mass production, screen printing shines. It allows for swift and efficient printing of large quantities, making it a preferred choice for events, corporate merchandise, and promotional campaigns.

Versatility in Fabric Compatibility

Screen printing can be used on various materials, including cotton, polyester, and blends, offering flexibility when choosing fabric types for your custom designs.

Disadvantages of Screen Printing

Time-Consuming

Screen printing can be a time-consuming process, especially when multiple colors are involved. Each color requires a separate screen and individual printing.

Not Ideal for Multicolored Designs

While screen printing can handle multiple colors, each additional color adds complexity to the process and may increase costs.

Less Durable Than Heat Transfer Vinyl

The ink used in screen printing sits on top of the fabric, making it slightly less durable than Heat Transfer Vinyl, which becomes a part of the fabric.

Heat Transfer Vinyl vs. Screen Printing: Key Differences

Both heat transfer vinyl and Screen Printing have their strengths and limitations. The key differences lie in their application process, cost-effectiveness, color range, and durability. Heat Transfer Vinyl excels in intricate designs and small orders, while Screen Printing is the go-to option for large-scale production and budget-friendly solutions.

Which Method to Choose?

Deciding between heat transfer vinyl and Screen Printing depends on various factors. Consider the following when making your choice:

Order Size

For small orders or individual designs, heat transfer vinyl might be more suitable due to its lower setup costs and flexibility.

Design Complexity

If your design is intricate and multicolored, heat transfer vinyl might be the better choice for preserving details.

Fabric Type

Consider the fabric material and its compatibility with the chosen printing method. Screen printing works well on a wide range of fabrics, but heat transfer vinyl might be a better fit for certain materials.

Factors to Consider

While choosing between heat transfer vinyl and Screen Printing, consider the following factors:

Cost Comparison

Evaluate your budget and the overall cost for the desired number of items. Compare the prices of both methods and choose the one that best aligns with your budget.

Quality Comparison

Assess the final output quality for both heat transfer vinyl and Screen Printing. Pay attention to details, color vibrancy, and overall appearance.

Longevity Comparison

Consider the expected lifespan of the printed design. Determine whether durability is a priority for your specific project.

In conclusion, both heat transfer vinyl and Screen Printing have their unique advantages and disadvantages. The choice between the two methods depends on your specific requirements, budget, and desired outcomes. Heat Transfer Vinyl excels in intricate designs and small orders, while Screen Printing is ideal for large-scale production and budget-conscious projects. By considering factors such as order size, design complexity, fabric type, cost, quality, and longevity, you can confidently select the best printing method for your custom apparel needs.

FAQs

Heat Transfer Vinyl is better suited for intricate and multicolored designs due to its ability to maintain fine details.

Screen Printing is generally more cost-effective for larger quantities, as the price per unit decreases with increased order size.

Heat Transfer Vinyl can be used on a wide range of fabrics, including cotton, polyester, and some blends.

When applied correctly, heat transfer vinyl designs can last for a long time, even with frequent washing and use.

Yes, it is possible to combine both printing methods in a single design, depending on the complexity and desired effect. However, this may increase production time and cost.