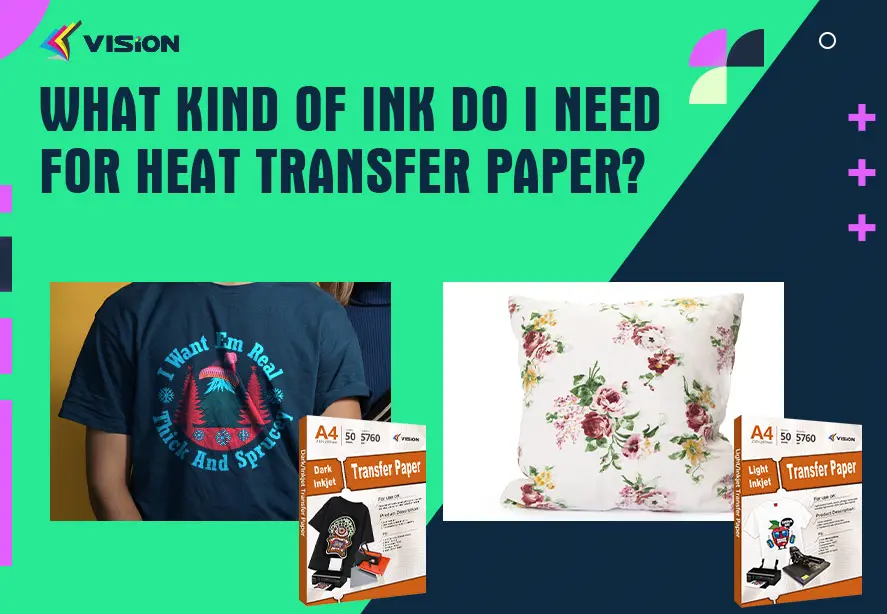

Heat Transfer Paper vs. Other Printing Methods: Pros and Cons

When customizing apparel, selecting the appropriate printing method is essential. Among the diverse options, heat transfer paper is notable for its unique benefits. This article will explore the pros and cons of heat transfer paper in comparison to other popular printing techniques like screen printing, direct-to-garment (DTG) printing, heat transfer vinyl (HTV) printing, direct-to-film (DTF) printing, and sublimation printing. Our goal is to provide you with a thorough understanding to aid in making an informed decision for your printing requirements.

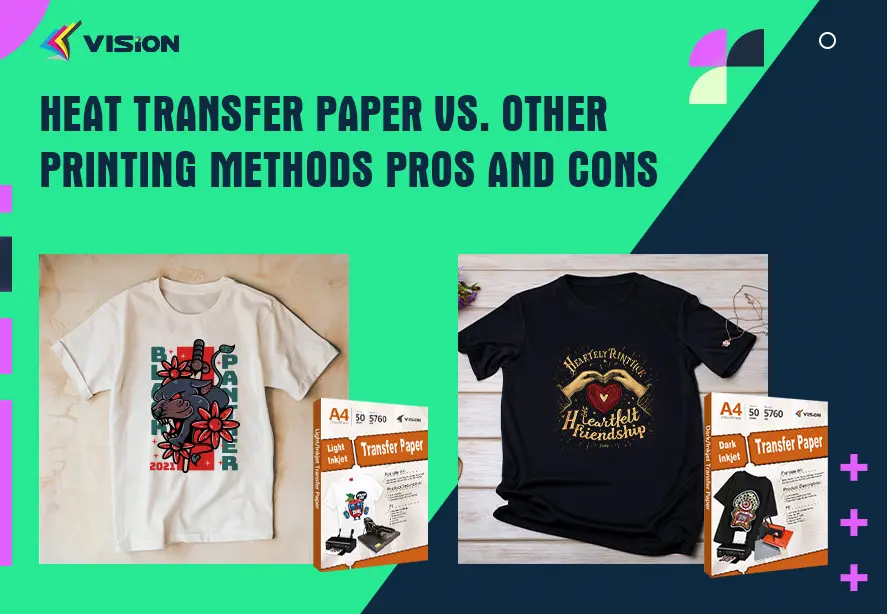

Pros of Heat Transfer Paper

1. Versatility

Heat transfer paper is highly versatile, usable on various materials including cotton, polyester, blends, and some hard surfaces. This flexibility makes it suitable for multiple applications, from t-shirts and tote bags to ceramic mugs and mousepads.

2. High-Quality Output

Heat transfer paper delivers vibrant and high-resolution prints, making it ideal for detailed and colorful designs. The image quality is often comparable to other advanced printing methods, making it perfect for custom prints where image clarity and color accuracy are crucial.

3. Cost-Effective for Small Runs

For small print runs, heat transfer paper is cost-effective. Unlike screen printing, which involves significant setup costs, heat transfer printing requires minimal setup. This makes it a preferred choice for small businesses, hobbyists, and one-off custom prints.

4. Ease of Use

Using heat transfer paper is straightforward. With basic equipment like an inkjet printer and a heat press, anyone can create professional-quality prints. This ease of use makes it accessible to beginners and those looking to start a small printing business from home.

Ease of Use

Cons of Heat Transfer Paper

1. Durability Issues

While heat transfer paper prints look great initially, they may not be as durable as other printing methods. Over time, with repeated washing and wearing, the prints can fade, crack, or peel. Proper care, such as washing inside out and using mild detergents, can help extend the lifespan of the prints.

2. Limited Fabric Compatibility

Although versatile, heat transfer paper has limitations regarding fabric compatibility. It works best on pure cotton light-colored fabrics and dark-colored fabrics or fabrics with a cotton content of more than 60%.

3. Time-Consuming for Large Orders

For large orders, using heat transfer paper can be time-consuming. Each piece needs to be individually printed, placed, and pressed, which can be labor-intensive compared to methods like screen printing or DTG printing that are more efficient for bulk production.

Comparing Heat Transfer Paper with Other Printing Methods

Screen Printing

Screen printing involves creating a stencil (or screen) and using it to apply layers of ink on the printing surface.

Pros:

Durability: Screen prints are highly durable and can withstand numerous washes without fading.

Cost-Effective for Large Runs: Ideal for large orders, as the cost per unit decreases with higher quantities.

Vibrant Colors: Produces vibrant colors and is excellent for simple designs with few colors.

Cons:

Setup Costs: Requires significant setup, making it less cost-effective for small runs.

Limited Detail: Not suitable for highly detailed or multi-colored designs.

Direct-to-Garment (DTG) Printing

DTG printing uses inkjet technology to print directly onto the fabric.

Pros:

High Detail: Excellent for detailed and colorful designs.

No Setup Costs: Minimal setup makes it ideal for small orders and one-offs.

Soft Feel: The prints have a soft feel since the ink is absorbed by the fabric.

Cons:

Cost: More expensive for larger orders compared to screen printing.

Limited Fabric Types: Works best on 100% cotton fabrics.

Heat Transfer Vinyl Printing

HTV printing involves cutting designs from vinyl sheets and using heat to transfer them onto fabrics.

Heat Transfer Vinyl Printing

Pros:

Durability: HTV prints are durable and can withstand multiple washes.

Versatile Designs: Ideal for simple designs and lettering, offering a range of colors and finishes.

No Setup Costs: Easy setup, suitable for small runs and custom designs.

Cons:

Complex Designs: Not suitable for highly detailed or multi-colored designs.

Layering: Complex designs require multiple layers, which can be time-consuming and add bulk to the fabric.

Direct-to-Film (DTF) Printing

DTF printing involves printing designs onto a special film, which is then transferred onto the fabric using heat and pressure.

DTF Printing

Pros:

Detail and Color: Produces high-quality, detailed prints with vibrant colors.

Versatility: Can be used on a wide range of fabrics, including cotton, polyester, and blends.

Durability: Prints are durable and can withstand multiple washes without fading or cracking.

Cons:

Equipment Cost: Requires specialized equipment and materials.

Complex Process: The process can be more complex and time-consuming compared to other methods.

Sublimation Printing

Sublimation printing involves turning solid dye into gas without passing through a liquid state, which bonds with polyester fabric.

Sublimation Printing

Pros:

Durability: Extremely durable, with prints that won’t fade, crack, or peel.

All-Over Printing: Allows for full-coverage printing over the entire surface of the garment.

Vibrant Colors: Produces bright and vibrant colors.

Cons:

Fabric Limitation: Only works on polyester or polyester-coated surfaces.

Initial Investment: Requires specialized equipment and materials.

Each printing method has its own set of advantages and disadvantages. Heat transfer paper offers versatility, high-quality output, cost-effectiveness for small runs, and ease of use, making it a great choice for many applications. However, it does have some durability issues and may not be the best option for large orders or certain fabric types.

By understanding the pros and cons of each method, you can choose the one that best fits your needs. Whether you’re a small business owner, a hobbyist, or someone looking to create custom apparel, there’s a printing method out there that’s perfect for you.

Related:

10 advantages of heat transfer paper

Heat Transfer Paper for Personalized Clothing

The Difference Between Iron-On Transfer Paper and Heat Transfer Paper