Fabric transfer paper

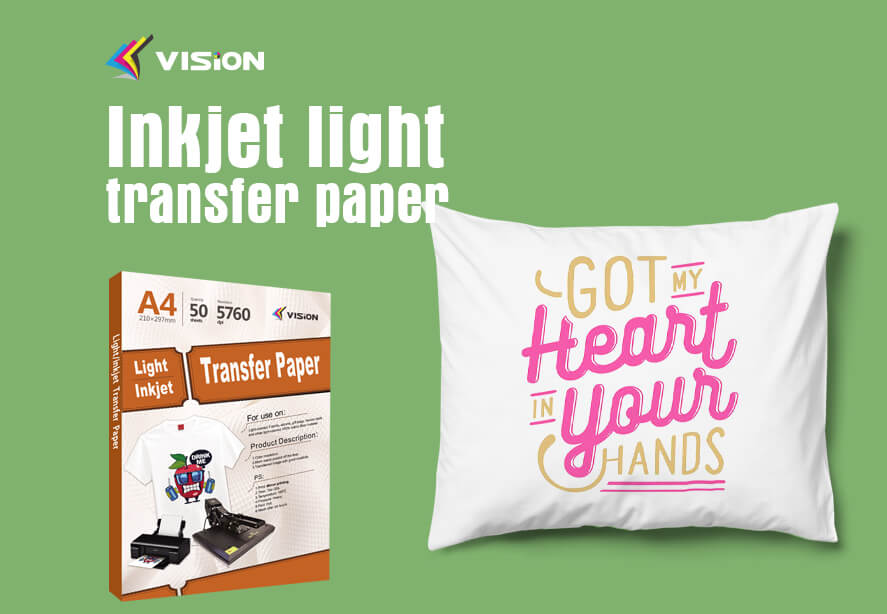

This is a video about how to use vision inkjet light heat transfer paper for tshirt business? More videos, please follow VISION youtube.

Wide application of fabric transfer paper

Fabric transfer paper offers a wide range of creative possibilities. It can be used to transfer designs onto various fabric types, including cotton, polyester, canvas, and more. It’s commonly used for personalizing T-shirts, tote bags, pillowcases, aprons, and other fabric items, as well as for creating custom home decor, gifts, and crafts.

How to choose high quality fabric transfer paper?

When choosing transfer paper for fabric, there are a few key factors to consider:

Printer compatibility: Make sure the transfer paper is compatible with your printer type, whether it’s an inkjet printer, laser printer, or a sublimation printer. Using the correct type of transfer paper for your printer is essential for achieving the best results.

Fabric type: Consider the type of fabric you will be transferring the design onto. Some transfer papers are specifically designed for use with certain fabric types, such as cotton, polyester, or blends. Choose a transfer paper that is suitable for the specific fabric type you will be working with to ensure good adhesion and durability.

Image quality: Look for transfer paper that offers high-quality image reproduction. The image should be sharp, vibrant, and detailed to achieve professional-looking results on your fabric. Consider the resolution and color vibrancy of the transfer paper when making your selection.

Transfer method: Decide on the transfer method you will be using, whether it’s a heat press, an iron, or another heat source. Different transfer papers may require different heat settings, times, and pressure levels. Choose a transfer paper that is compatible with your chosen transfer method and follow the manufacturer’s instructions for best results.

Durability: Consider the durability requirements of your project. Some transfer papers may offer better durability than others, depending on the type of fabric, washability, and wear and tear the finished item will undergo. If you need a long-lasting transfer that can withstand multiple washes or heavy use, look for transfer papers that are specifically labeled as durable or have a reputation for good durability.

Ease of use: Choose a transfer paper that is easy to use and provides clear instructions. Look for transfer papers that offer good adhesion, easy peeling, and minimal chances of smudging or fading during the transfer process. User-friendly transfer papers can make your crafting experience more enjoyable and yield better results.

Cost: Consider your budget when selecting transfer paper for fabric. Transfer papers come in a range of prices, so choose one that fits within your budget while still meeting your quality and durability requirements.

Fabric transfer paper is a versatile and creative tool for personalizing fabrics and creating custom fabric items. When choosing transfer paper, consider printer compatibility, fabric type, image quality, transfer method, durability, ease of use, and cost. By selecting the right transfer paper for your specific project, you can achieve high-quality and durable results that will make your fabric creations truly unique and personalized.

Looking for high-quality heat transfer paper suppliers

VISION is a reputable transfer paper factory based in China. With years of experience in the industry, VISION offers a wide range of high-quality transfer papers designed specifically for fabric applications.

Ease of use is a hallmark of VISION’s fabric transfer papers. Their transfer papers offer good adhesion, easy peeling, and minimal chances of smudging or fading during the transfer process. Clear instructions are provided, making it easy for users to achieve professional-quality results, even if they are new to fabric transfer.

As a leading manufacturer, VISION understands the needs of crafters, DIY enthusiasts, and businesses looking to create custom fabric items with ease. Our transfer papers are printer-compatible, suitable for different fabric types, offer high image quality, are compatible with various transfer methods, known for their durability and easy to use With VISION’s fabric transfer papers, crafters, DIY enthusiasts, and businesses can create personalized fabric items with confidence and ease.