Essential Tools for Perfect Heat Transfer Vinyl

Whether you’re a seasoned crafter or just getting started, having the right tools can make all the difference in achieving perfect results. In this comprehensive article, we’ll explore the must-have tools and techniques for flawless HTV application on T-shirts. Let’s gear up for success and unleash our creativity!

Understanding Heat Transfer Vinyl

Before we dive into the tools, let’s briefly cover what heat transfer vinyl is and why it’s become a popular choice for customizing T-shirts.

Heat transfer vinyl, also known as HTV, is a special type of vinyl material that can be cut into designs, heated, and applied to various fabrics, including cotton, polyester, and blends. It offers a durable and professional-looking finish, making it ideal for creating custom T-shirts, apparel, and accessories.

How Does it Work?

HTV works through a process of heat application. Once a design is cut from the vinyl using a cutting machine, it is weeded to remove excess material. The design is then placed onto the desired surface and transferred using a heat press or iron. The heat activates the adhesive, causing it to bond securely to the fabric.

Essential Tools for Perfect Heat Transfer Vinyl

To achieve flawless results with heat transfer vinyl, you’ll need the following essential tools:

1. Cutting Machine

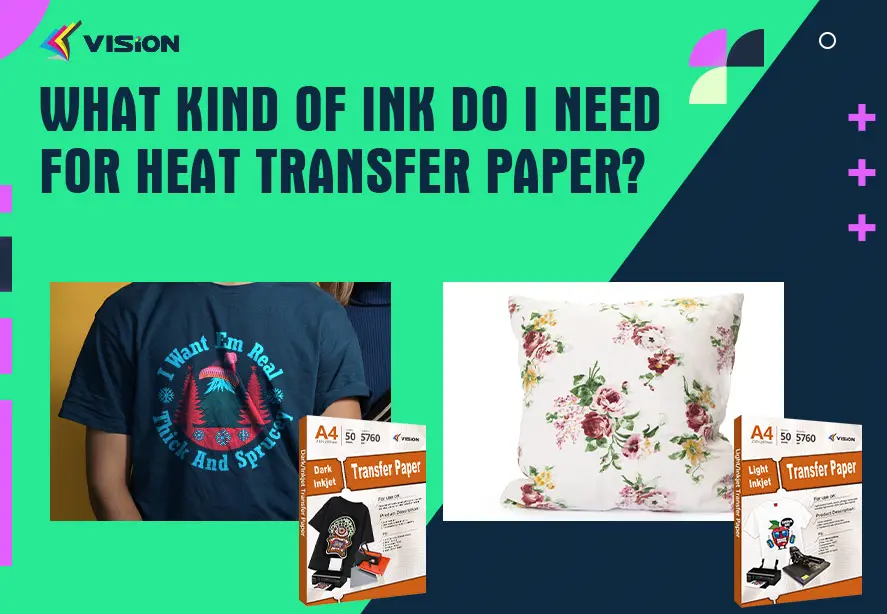

A cutting machine is indispensable for accurately cutting heat transfer vinyl designs. Look for a reliable machine that offers precise cuts and compatibility with various design software. Popular options include the Cricut Maker and Mecolour vinyl cutter.

2. Heat Press

A heat press is essential for applying heat and pressure to transfer the vinyl design onto the T-shirt. Unlike an iron, which can produce uneven heat distribution, a heat press ensures consistent temperature and pressure, resulting in professional-quality transfers every time. Invest in a quality heat press with adjustable temperature and pressure settings for optimal results. The Mecolour heat press is a favorite among professionals for its reliability and performance.

3. Weeding Tools

Weeding tools are used to remove the excess vinyl from around your design before transferring it onto the T-shirt. A weeding hook or tweezers are essential for removing excess vinyl from your designs. These tools allow for precise and delicate handling, ensuring clean and crisp results.

weed

4. Teflon Sheet

A teflon sheet is placed between the heat press and the vinyl design to protect both the design and the T-shirt from heat damage. It prevents scorching or sticking. It also helps distribute heat evenly, ensuring uniform transfers without any hot spots.

5. T-shirts and Fabric

Don’t forget the canvas for your creations! Stock up on high-quality T-shirts and other fabric items to showcase your heat transfer vinyl designs. Choose fabrics that are compatible with heat transfer vinyl, such as cotton or polyester blends.

6.Heat transfer vinyl

When selecting heat transfer vinyl for your projects, consider factors such as color, thickness, and durability. Opt for high-quality vinyl that is compatible with your cutting machine and heat transfer process.

VISION HTV Factory offers high quality heat transfer vinyl in a variety of colors and finishes to fit your design. There are a variety of options, from standard colors to metallic and glitter, more than 200 colors for your choice.

VISION heat transfer vinyl factory

7.Cutting Mat

A cutting mat provides a stable surface for your cutting machine and protects your work surface from damage. Look for a cutting mat that is compatible with your machine and offers sufficient grip to hold your material in place during cutting.

8.Heat Resistant Tape

Heat resistant tape is essential for transferring your design from the carrier sheet to the fabric. It holds the design in place during the heat press process, preventing shifting or misalignment. Look for heat-resistant and easy-to-peel transfer tape that won’t leave residue on your HTV or fabric.

9.Protective Gear

When working with heat transfer vinyl, it’s important to prioritize safety. Consider using protective gear such as heat-resistant gloves to protect your hands from the heat press and sharp weeding tools. Additionally, a heat-resistant workspace or mat can prevent accidental damage to surfaces.

Tips and Techniques for Success

Now that you have your essential tools, here are some tips and techniques to help you achieve perfect heat transfer vinyl application every time:

Preheat Your T-shirt: Before applying the vinyl, preheat the T-shirt with your heat press to remove any moisture and wrinkles, ensuring a smooth surface for application.

Use Proper Pressure: Adjust the pressure settings on your heat press according to the thickness of the fabric and vinyl. Too much pressure can cause the vinyl to crack, while too little pressure may result in incomplete adhesion.

Peel Hot or Cold?: Decide whether to peel the vinyl backing hot or cold based on the type of vinyl you’re using. Some vinyls are best peeled immediately after heat pressing, while others require cooling before peeling.

Test Cut Settings: Always perform test cuts on a small piece of vinyl to ensure the blade depth and pressure settings are correct for your material. This helps prevent wasted vinyl and ensures clean cuts.

Layering Vinyl: If you’re creating multi-color designs, layering vinyl allows you to achieve intricate designs with multiple colors. Be sure to use a Teflon sheet between layers to prevent the vinyl from melting together.

How To Layer Soft Metallic Heat Transfer Vinyl?

With the right tools and equipment, working with heat transfer vinyl becomes a breeze. By having these essential tools on hand, you’ll be well-equipped to create stunning designs on various fabrics using heat transfer vinyl. Get ready to unleash your creativity and enjoy the rewarding world of HTV crafting!

Related:

Mastering Heat Transfer Vinyl for T-Shirts Tips

Avoid the Pitfalls of Heat Transfer Vinyl Applications

9 Do’s and 9 Don’ts of Layering Heat Transfer Vinyl

FAQs

While an iron can be used for heat transfer vinyl application, a heat press provides more consistent heat and pressure, resulting in better adhesion and durability.

With proper application and care, heat transfer vinyl designs can last for years without fading or peeling. Always follow the manufacturer’s instructions for washing and caring for your vinyl creations.

Yes, heat transfer vinyl can be applied to a variety of fabrics and surfaces, including bags, hats, and even wood! Just be sure to choose the appropriate vinyl and adjust your heat press settings accordingly.