Blog

Can you use DTF film without adhesive powder?

Ever wondered if you can use DTF (Direct to Film) film without that crucial powder component? DTF printing has become a popular method for creating vibrant and durable prints on various materials. But what if you want to skip the adhesive powder? In this article, we’ll explore whether you can do without the powder, and weigh the pros and cons of this approach.

Understanding DTF Powder

What is DTF Powder?

DTF powder is an adhesive powder that sticks to the printed ink on the film. It acts as a bonding agent, helping the ink adhere properly to the fabric during the heat transfer process.

How Does DTF Powder Work?

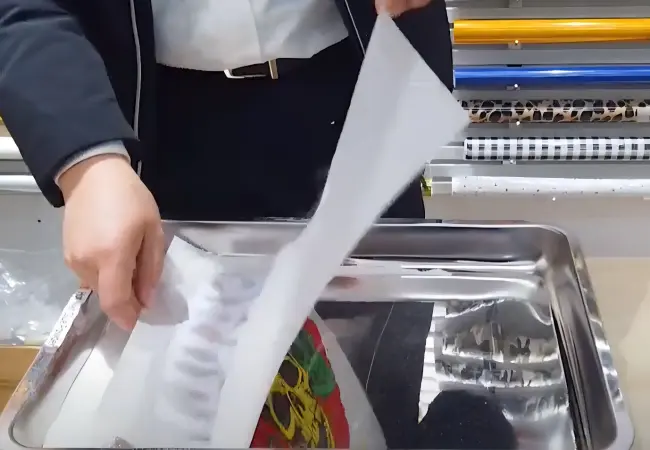

After printing your design onto the DTF film, you sprinkle the adhesive powder onto the still-wet ink. This powder is then melted in a curing oven, forming a solid layer that bonds the ink to the fabric when heat pressed.

Can You Skip the adhesive Powder?

Pros and Cons of Using DTF Film Without Powder

So, can you really use DTF film without powder? Let’s break it down.

Pros of Not Using adhesive Powder

Simplicity: Omitting the powder step simplifies the process, reducing the number of steps and materials needed.

Cost Savings: You’ll save money by not purchasing the powder.

Cons of Not Using adhesive Powder

Adhesion Issues: Without powder, the ink might not bond properly to the fabric, leading to poor print durability and potential peeling.

Quality Compromise: The absence of powder can affect the quality of the print, leading to faded or uneven results.

Using dtf Powder

Alternative Methods

If you’re considering skipping the powder, you might want to explore alternative methods like using pre-coated transfer films or adjusting your printing process to compensate for the lack of powder.

Why the adhesive powder is essential?

Adhesion: The powder melts during the heat pressing process, creating a strong bond between the ink and the substrate. Without the powder, the ink may not adhere properly, leading to poor transfer quality and potential lifting or peeling.

Durability: The adhesive powder helps to ensure that the transfer is durable and can withstand washing and wear. It helps the print stay intact and prevents issues like cracking or fading.

Smooth Application: The adhesive powder helps to ensure an even application of the ink and reduces the risk of uneven spots or gaps in the transfer.

How To Use Vision DTF Transfer Film Step by Step?

When to Use Powder?

Best Practices for DTF Printing

For the best results, using the powder as intended is crucial. It ensures that your prints are vibrant and long-lasting. Follow these practices for optimal results:

Use high-quality powder that matches your film and ink.

Ensure even application of powder for consistent prints.

Follow the manufacturer’s instructions for curing and heat pressing.

Choosing the Right Powder

Different powders are available, each designed for specific types of fabrics and inks. Research and select a powder that complements your materials for the best outcome.

In summary, while it might be tempting to skip the powder in DTF printing, it’s generally not advisable. The adhesive powder plays a critical role in ensuring your prints adhere well and last long. For the best results, stick to the recommended process, including the use of powder, to achieve vibrant and durable prints.

Related:

DTF powder for printing

FAQs

Using DTF film without powder can result in poor adhesion of the ink to the fabric, leading to prints that may peel or fade over time.

It’s challenging to achieve high-quality, durable results without powder. The powder helps ensure that the ink bonds properly to the fabric.

Common types of DTF powder include hot-melt powders and cold-melt powders, each suited for different types of fabrics and inks.

While there are some alternatives, using the recommended DTF powder is generally the best way to ensure quality results. Substitutes might not provide the same level of adhesion.

To apply DTF powder, sprinkle it evenly over the wet ink on the film, ensuring complete coverage. Then cure the powder according to the manufacturer’s instructions before heat pressing.