Blog

Can I Use Heat Transfer Paper on Dark Fabrics?

Heat transfer paper has revolutionized the world of custom apparel, offering a simple yet effective way to create personalized designs on various types of fabrics. However, one common question arises: Can I use heat transfer paper on dark fabrics? The short answer is yes, but there are specific considerations and techniques to ensure the best results.

Understanding Heat Transfer Paper

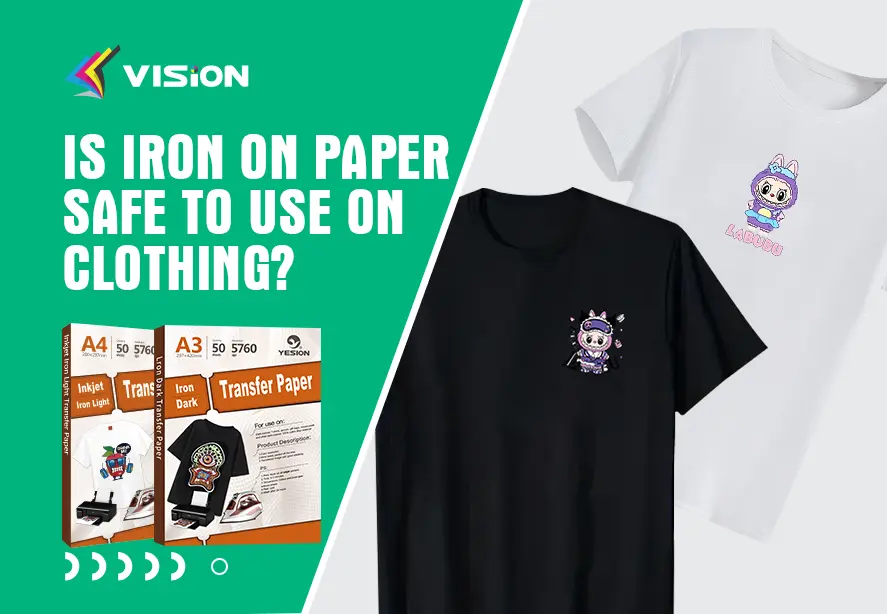

Heat transfer paper is a special kind of paper used to transfer printed designs onto fabrics. The process involves printing a design onto the transfer paper and then using heat and pressure to transfer the design onto the fabric. There are two main types of heat transfer paper: light transfer paper and dark transfer paper.

Light Transfer Paper vs. Dark Transfer Paper

Light transfer paper is designed for use on white or light-colored fabrics. It allows the colors of the design to blend seamlessly with the fabric. However, when used on dark fabrics, light transfer paper can produce unsatisfactory results, as the design may not be visible or vibrant.

Dark transfer paper, on the other hand, is specifically formulated for use on dark or colored fabrics. It has an opaque white backing that prevents the color of the fabric from showing through the design, ensuring that the colors remain vibrant and visible.

How to Use Heat Transfer Paper on Dark Fabrics

Using heat transfer paper on dark fabrics requires a different approach compared to light fabrics. Here are the steps to follow for optimal results:

Materials Needed

Dark transfer paper

Inkjet printer

Heat press or iron

Teflon sheet or parchment paper

Dark fabric (e.g., t-shirts, hoodies)

Scissors or cutting machine

Materials Needed

Step-by-Step Guide

Prepare Your Design: Create or select a design using graphic design software. Make sure to mirror the design if it includes text or specific orientation elements.

Print the Design: Load the dark transfer paper into your inkjet printer, ensuring it is oriented correctly. Print the design onto the transfer paper. Allow the ink to dry completely.

Cut Out the Design: Carefully cut out the printed design, leaving a small margin around the edges. If you have a cutting machine, you can use it for more precise cuts.

Preheat the Fabric: Preheat the fabric by pressing it with a heat press or iron for a few seconds. This removes any moisture and wrinkles, providing a smooth surface for the transfer.

Position the Transfer Paper: Place the cut-out design onto the fabric with the printed side facing up. Cover the design with a Teflon sheet or parchment paper to protect it from direct heat.

Apply Heat and Pressure: Use a heat press or iron to apply heat and pressure to the transfer paper. Follow the manufacturer’s instructions for temperature and time settings. Typically, a heat press is set to 350°F (177°C) and pressed for 20-30 seconds. If using an iron, apply firm pressure evenly over the entire design for 20-30 seconds. For specific settings, please refer to the product manual you purchased.

Cool and Peel: Allow the transfer to cool for a few minutes. Once cool, carefully peel off the backing paper. The design should now be transferred onto the fabric.

How to use Vision inkjet dark heat transfer paper for cotton tshirt?

Tips for Best Results

Use High-Quality Transfer Paper: Investing in high-quality dark transfer paper can make a significant difference in the final result. Cheap or low-quality paper may not transfer well or may not withstand washing.

Test Before Full Application: Always test the transfer process on a small piece of fabric or an inconspicuous area before applying the design to the entire garment. This helps you fine-tune the heat and pressure settings.

Wash and Care Instructions: To ensure the longevity of the transferred design, wash the fabric inside out in cold water and avoid using harsh detergents or bleach. Line dry or tumble dry on low heat.

Avoid Stretching the Fabric: Stretching the fabric after the transfer can cause the design to crack or peel. Handle the garment with care to maintain the integrity of the transfer.

Common Mistakes to Avoid

Using Light Transfer Paper on Dark Fabrics: As mentioned earlier, light transfer paper is not suitable for dark fabrics. Always use dark transfer paper for the best results on colored or dark garments.

Incorrect Temperature or Pressure: Applying too much or too little heat and pressure can affect the transfer quality. Follow the manufacturer’s guidelines closely and make adjustments as needed.

Advantages of Using Heat Transfer Paper on Dark Fabrics

Using heat transfer paper on dark fabrics offers several benefits:

Customization: It allows for personalized designs, making it ideal for creating unique apparel for events, businesses, or personal use.

Vibrant Colors: Dark transfer paper ensures that colors remain vibrant and true to the original design, even on dark backgrounds.

Cost-Effective: Compared to other printing methods, heat transfer paper is a cost-effective solution for small-scale or one-off projects.

Ease of Use: The process is relatively simple and can be done at home with basic equipment, making it accessible to hobbyists and small business owners.

dark transfers

In conclusion, using heat transfer paper on dark fabrics is entirely feasible with the right materials and techniques. By following the steps outlined in this guide and avoiding common mistakes, you can achieve professional-quality transfers that are vibrant, durable, and eye-catching. Whether you’re creating custom t-shirts for a special event or starting a small apparel business, understanding how to use heat transfer paper on dark fabrics will help you produce exceptional results.

Related:

Inkjet vs. Laser for Dark Fabric Transfer Paper

Choosing the Best Dark Fabric Transfer Paper