Can I Use Any Inkjet Printer for Heat Transfers?

When it comes to heat transfers, choosing the right printer can make all the difference in the quality of your prints. Inkjet printers are a popular choice for heat transfer applications, but not all inkjet printers are created equal. The type of printer and ink you use can significantly impact the durability, vibrancy, and clarity of your heat transfer prints. In this comprehensive guide, we will explore everything you need to know about using inkjet printers for heat transfers—from choosing the right printer and ink to tips for getting the best results.

What is Heat Transfer Printing?

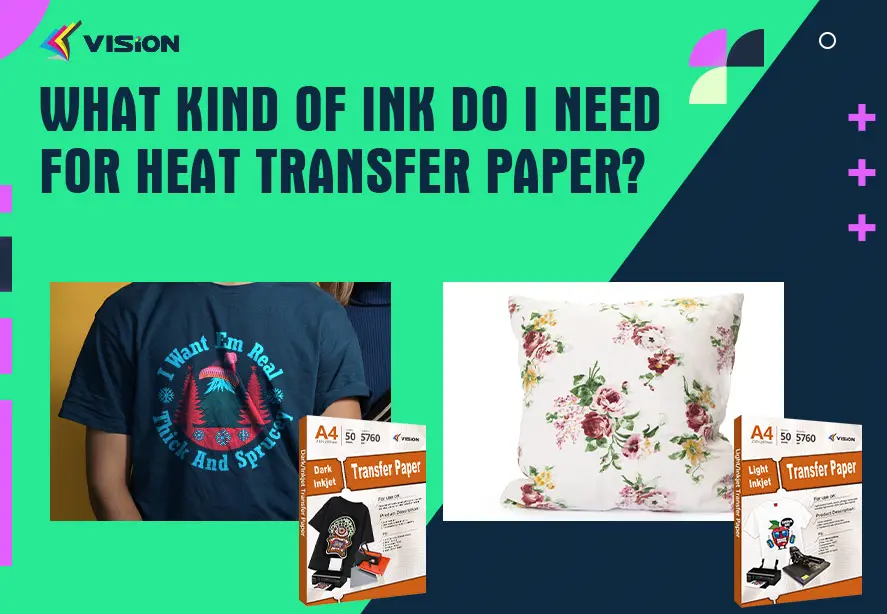

Heat transfer printing is a popular method used to apply images, logos, or designs onto fabrics or other materials. The process involves printing an image onto a special transfer paper using a printer, and then applying heat and pressure to transfer the design onto the material. The transfer process can be used for a variety of materials, including t-shirts, mugs, bags, and other fabric items.

For heat transfers, inkjet printers are often chosen because they provide high-resolution prints and are widely available. However, not all inkjet printers are suitable for this type of printing. Understanding which printers and inks are optimal for heat transfers will help you achieve better results and avoid costly mistakes.

Can Any Inkjet Printer Be Used for Heat Transfers?

Technically, any inkjet printer can be used for heat transfers, but not all of them are optimized for the task. To get high-quality heat transfer prints, it’s essential to consider several factors:

Printer Compatibility

Inkjet Printers with Dye-Based Inks: Some inkjet printers use dye-based inks, which are more suitable for vibrant, rich color reproduction. These inks work well for heat transfers onto light-colored fabrics. However, dye-based inks may not be as durable when exposed to washing and wear over time.

Inkjet Printers with Pigment-Based Inks: Pigment-based inks tend to produce more fade-resistant prints, which is ideal for transferring designs onto dark fabrics. Pigment inks offer greater durability and longer-lasting prints, making them a good choice for projects that require durability.

Printer Settings: Not all printers come with preset settings specifically for heat transfers. Printers with adjustable settings (such as paper type and quality settings) are preferred for heat transfer printing. These adjustments help optimize print quality and ensure the best results when transferring designs.

Inkjet transfer paper for light fabrics

Type of Ink for Heat Transfers

The type of ink you use in your inkjet printer will play a crucial role in the final result of your heat transfer prints. There are three main types of ink to consider for heat transfer printing:

Dye-Based Inks: These inks are water-based and tend to produce bright, vibrant colors. However, they are not as durable as pigment-based inks and may fade over time, especially after repeated washing. Dye-based inks are suitable for light-colored fabrics and are most commonly used for iron-on transfers.

Pigment-Based Inks: These inks consist of solid particles that are suspended in liquid and are more resistant to fading than dye-based inks. They are ideal for dark fabrics because they produce crisp, long-lasting prints. Pigment-based inks are less likely to smudge or run, providing more durability.

Sublimation Inks: While sublimation inks require a sublimation printer, they are worth mentioning because of their excellent quality and long-lasting results. Sublimation inks work by turning into gas when heated and bonding with polyester fibers, making them highly durable. However, sublimation is not ideal for cotton or other non-synthetic fabrics.

Choosing the Right Inkjet Printer for Heat Transfers

When selecting an inkjet printer for heat transfer printing, there are several factors to consider to ensure optimal performance and print quality.

Printer Resolution

The resolution of your printer affects the sharpness and clarity of your prints. Printers with a high resolution (such as 1440 x 1440 dpi) will produce finer details and more vibrant colors, which is essential for high-quality heat transfer prints. Printers with low resolution may result in blurry or pixelated images that won’t transfer well onto fabric.

Printer Compatibility with Transfer Paper

Not all transfer papers are the same, and some printers work better with specific types of transfer paper. For instance, some printers are optimized for laser transfer papers, while others work best with inkjet transfer papers. Make sure the printer you choose is compatible with the type of transfer paper you intend to use.

Printer Size and Speed

Consider the size and speed of the printer, especially if you plan to print large designs or produce multiple heat transfers at once. A printer with a larger printing bed and faster printing speed will help you handle bigger projects more efficiently.

Cost of Ink and Maintenance

While inkjet printers can be affordable, the long-term cost of ink and maintenance can add up. When choosing a printer, consider the cost of replacement ink cartridges and whether the printer requires frequent maintenance. Some printers are designed for heavy use and can withstand the demands of a high-volume heat transfer business, while others may not be as durable.

Tips for Successful Heat Transfer Printing

Even with the right printer, getting high-quality heat transfer prints requires some know-how. Here are a few tips to help you achieve the best results:

1. Use High-Quality Transfer Paper

Choosing high-quality transfer paper is essential for a successful heat transfer print. Look for transfer papers that are specifically designed for use with inkjet printers. These papers are usually coated to allow ink to sit on the surface rather than being absorbed into the paper, ensuring better color saturation and transfer.

2. Adjust Printer Settings

Make sure your printer settings are optimized for heat transfers. Use the best quality print settings, and adjust the paper type to match the transfer paper you are using. This will help prevent ink smudging or uneven prints.

3. Preheat Your Material

Before applying the heat transfer, preheat the fabric or material for a few seconds using a heat press or iron. This helps remove any moisture from the surface, ensuring that the transfer adheres more effectively.

iron press and heat press

4. Use the Right Temperature and Pressure

Follow the manufacturer’s instructions for temperature and pressure when applying the heat transfer. Too much heat or pressure can damage the fabric or cause the design to fade prematurely.

5. Allow the Print to Cool Before Handling

After completing the heat transfer process, allow the item to cool before touching or moving it. This ensures that the design has fully adhered to the material and reduces the risk of smudging.

While it’s possible to use any inkjet printer for heat transfers, the quality of the printer and ink you choose will significantly impact the final results. For best results, opt for a high-resolution printer with pigment-based inks and ensure that it is compatible with the transfer paper you plan to use.

Related:

Differences Between Sublimation Printing and Heat Transfer Printing

How to choose the ink used for inkjet heat transfer paper, pigment ink or dye ink?

The comparison of Inkjet light heat transfer paper 1.0 and 2.0

Best Inkjet Heat Transfer Paper for T-Shirts