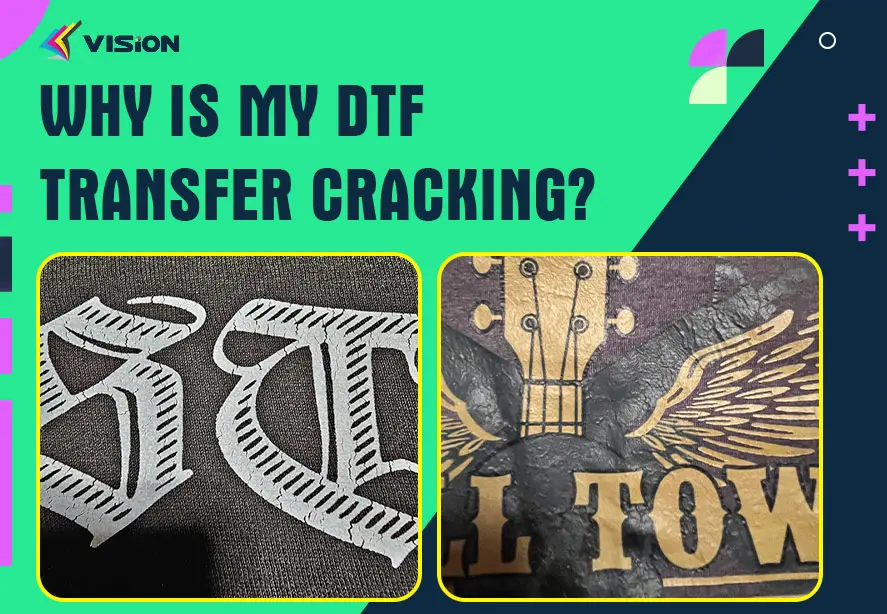

Why is my DTF transfer cracking?

DTF (Direct-to-Film) transfers have revolutionized the world of custom apparel and other textiles, offering vivid prints and a versatile application process. However, despite its many advantages, DTF transfers sometimes face issues like cracking, which can significantly affect the quality and longevity of the finished product. In this article, we’ll explore the common causes of DTF transfer cracking, how to prevent it, and what to do if it happens to your prints.

Common Reasons for DTF Transfer Cracking

Cracking in DTF transfers can be frustrating, especially when you’re aiming for a durable and professional finish. Here are the most common reasons why your DTF transfers might be cracking:

Incorrect Temperature Settings

Temperature plays a crucial role in the DTF transfer process. If the heat press temperature is too high or too low, it can cause the transfer to crack. High temperatures can cause the ink and adhesive to over-cure, leading to brittleness, while low temperatures might not allow the adhesive to bond properly, resulting in weak transfers that crack easily.

Inadequate Pressure Application

Just like temperature, pressure is vital in ensuring that the DTF transfer adheres smoothly to the fabric. If the pressure applied during the heat pressing process is too low, the transfer might not fully adhere, leading to cracks. On the other hand, excessive pressure can squeeze out too much adhesive, causing the design to crack as it cools.

Poor Quality Film or Ink

The quality of the film and ink used in DTF transfers can also impact the durability of the transfer. Using substandard materials can result in weak bonds that are prone to cracking. High-quality DTF films and inks are specifically designed to withstand the stresses of heat pressing and subsequent wear and tear, so it’s important to choose reliable suppliers.

dtf transfer

Improper Curing Process

Curing is the process that sets the adhesive powder onto the printed design, making it ready for transfer. If this step is not done correctly, it can lead to cracking. For instance, under-curing the adhesive might cause it to peel off the fabric, while over-curing can make the transfer brittle.

Old or Expired Materials

Materials used in DTF transfers, like inks and films, have a shelf life. Using old or expired materials can lead to poor transfer results, including cracking. As inks age, they can lose their bonding strength, and films might not adhere as well, leading to issues during the heat press stage.

Inappropriate Fabric Selection

Not all fabrics are suitable for DTF transfers. Certain fabrics, especially those with rough or uneven surfaces, might not provide the smooth contact needed for a proper transfer. Fabrics with high elasticity, such as spandex, can also cause the transfer to stretch and crack.

How to use DTF film?

Preventing Cracking in DTF Transfers

Now that we’ve identified some common causes, let’s look at how to prevent cracking in your DTF transfers:

Choosing the Right Materials

Always opt for high-quality DTF films and inks. While these may be more expensive, they are crucial for producing durable transfers. Look for products from reputable suppliers and check for reviews or industry certifications.

Proper Equipment Calibration

Ensure your heat press is properly calibrated. This means setting the correct temperature and pressure according to the specifications of the film and ink you’re using. Regularly check your equipment to make sure it’s functioning correctly.

Curing Techniques

Curing is a critical step that needs precision. Make sure to follow the recommended curing time and temperature settings for the adhesive powder you’re using. A small test run before full production can help avoid costly mistakes.

Testing Before Production

Before committing to a large run, it’s wise to test the DTF transfer on a sample of the fabric you’re planning to use. This test will help you adjust your settings to avoid DTF transfer cracking or other issues.

Storage and Handling of Materials

Store your DTF materials in a cool, dry place away from direct sunlight. Proper storage extends the shelf life of inks and films and maintains their effectiveness. Always seal unused materials properly to avoid contamination or drying out.

Troubleshooting Cracked DTF Transfers

If you’re already dealing with cracked DTF transfers, don’t worry—there are ways to troubleshoot and fix the issue:

Identifying the Problem Source

Examine the cracked areas closely. If the cracks appear in random places, it might be an issue with temperature or pressure. Consistent cracking in specific areas could indicate a problem with the fabric or the film itself.

Correcting Temperature and Pressure Issues

Adjust your heat press settings. Increase or decrease the temperature gradually to see if it improves the transfer quality. Similarly, tweak the pressure settings until you find the optimal combination that eliminates DTF transfer cracking.

Replacing Faulty Materials

If your troubleshooting points to low-quality or expired materials, it’s time to replace them. Invest in fresh, high-quality inks and films. While this might seem costly, it’s more efficient than dealing with repeated transfer failures.

Cracking in DTF transfers can be a frustrating problem, but with careful attention to detail, it can be avoided. By understanding the importance of proper temperature, pressure, curing, and material selection, you can create long-lasting, crack-free transfers that will keep your customers satisfied. Always remember to test your equipment and materials before full-scale production to ensure the best results.