Troubleshooting Common DTF Printing Issues

Direct-to-Film (DTF) printing is revolutionizing the textile printing industry with its vibrant colors and versatility. But, like any advanced technology, it comes with its own set of challenges. Whether you’re a seasoned pro or just starting out, troubleshooting common DTF printing issues is crucial for ensuring high-quality prints and efficient workflows. In this guide, we’ll delve into some of the most frequent problems faced by DTF printers and provide practical solutions to help you master your craft.

Common DTF Printing Issues and How to Fix Them

Issue 1: Ink Smudging

Problem: You notice smudges or streaks in your prints, leading to a messy and unprofessional look.

Solution:

Check Ink Levels: Ensure that your printer’s ink levels are adequate. Low ink can cause irregularities in printing.

Drying Time: Allow sufficient drying time between printing and transferring. Rushed processes can lead to smudging.

Use High-Quality Films: Low-quality films may not handle the ink properly, leading to smudges. Investing in premium films can prevent this issue.

Issue 2: Poor Adhesion to Fabric

Problem: The print does not adhere properly to the fabric, leading to peeling or lifting.

Solution:

Correct Temperature and Pressure: Ensure that your heat press is set to the right temperature and pressure. Different fabrics require different settings.

Pre-Pressing: Pre-press the fabric to remove any moisture and wrinkles before applying the DTF transfer.

Adhesive Powder: Use an appropriate adhesive powder and ensure it is evenly applied to the film.

Issue 3: Color Inconsistency

Problem: The colors in your prints don’t match the original design, appearing either too dull or overly saturated.

Solution:

Color Profiles: Use ICC color profiles tailored to your printer and ink to ensure accurate color reproduction.

Maintenance: Regularly clean your printer heads and ensure they are aligned correctly.

Quality Control: Perform test prints and adjust your settings as needed before running full production.

Issue 4: Film Jamming in Printer

Problem: The film gets jammed in the printer, disrupting the printing process and potentially damaging the printer.

Solution:

Proper Loading: Ensure that the film is loaded correctly and is compatible with your printer model.

Printer Settings: Adjust the printer settings to match the thickness and type of film being used.

Regular Cleaning: Keep the printer rollers clean and free from debris to prevent jams.

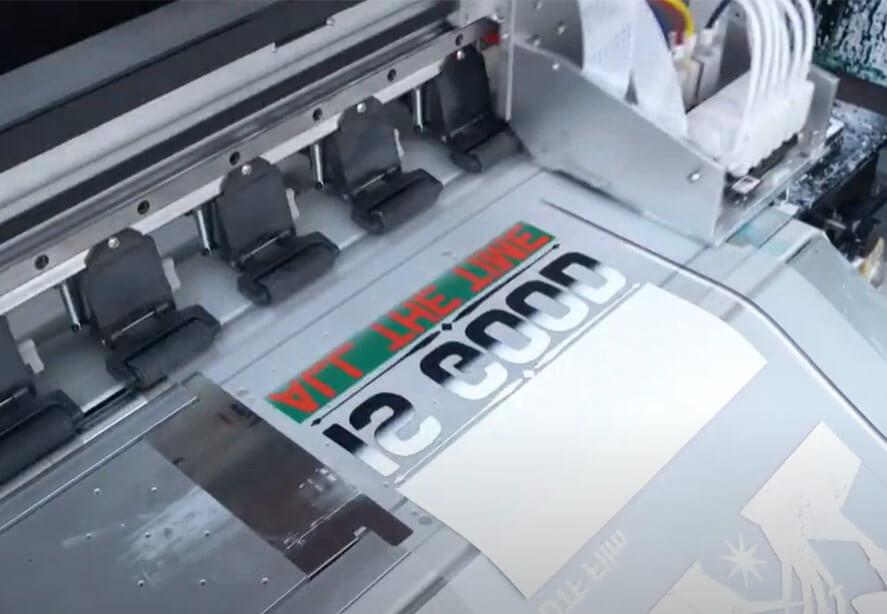

dtf printer printing

Issue 5: Print Cracking or Fading

Problem: Over time, the prints crack or fade, diminishing the quality and longevity of the product.

Solution:

Correct Curing: Make sure the prints are cured at the right temperature for the appropriate amount of time.

Fabric Compatibility: Use fabrics that are known to hold DTF prints well. Some fabrics may not be ideal for DTF printing.

Protective Coating: Consider applying a protective coating to enhance the durability of the prints.

Advanced Troubleshooting Techniques

Fine-Tuning Print Settings

Adjusting your print settings can make a world of difference. Here are some tips:

Resolution: Higher resolution settings can improve print quality but may require more time.

Ink Density: Adjusting the ink density can help achieve the desired color intensity.

Speed: Slowing down the printing speed can enhance the detail and quality of your prints.

Regular Maintenance and Upkeep

Routine maintenance is key to avoiding many common issues:

Printer Cleaning: Regularly clean the printer heads, rollers, and other components.

Software Updates: Keep your printer firmware and software up-to-date to ensure optimal performance.

Spare Parts: Have spare parts on hand, such as print heads and rollers, to quickly address any hardware issues.

Experimentation and Testing

Don’t be afraid to experiment:

Test Prints: Always perform test prints on different fabrics and films.

Sample Runs: Before committing to a large print run, do sample runs to identify and resolve any potential issues.

Troubleshooting common DTF printing issues doesn’t have to be daunting. By understanding the root causes of these problems and applying the right solutions, you can significantly improve the quality and reliability of your prints.